Waste oil refers to those oils that are purified or synthesized from crude oil and are contaminated by physical or chemical impurities after use. Simply put, waste oil, as its name suggests, is the oil that has been used that originated from petroleum or synthetic oil. During normal use, impurities such as dust, metal shavings, water, or chemicals may be mixed with the oil. When the oil is used for a long time, the oil can no longer play a good lubricating effect. At this time, the oil must be replaced with new oil or purified oil. The most common and environmentally friendly way to dispose of waste oil is to waste oil recycling and then process it so that the oil can be used again.

Why Do We Need Waste Oil Recycling?

In the past, waste oil was disposed of or incinerated. But this method can easily pollute the environment. With the continuous advancement of technology, the current waste oil treatment method is to reuse the waste oil after treatment. Recycling waste lubricating oil can not only make full use of resources, but also bring considerable economic benefits, and it also avoids environmental pollution problems caused by the random discarding of oil.

Five Steps for Recycling Waste Oil

- Settlement

Let the waste oil standstill to make the impurities fall and separate. Settling time is determined by oil quality and oil temperature. The higher the oil temperature, the smaller the viscosity, the easier it is for impurities to fall, and the shorter the settling time. There is professional sedimentation equipment in the professional waste oil recycling plant, which can make the waste oil settle and separate quickly and shorten the working time.

- Distillation

Put the waste engine oil after the sedimentation treatment to remove the sediment into the distillation flask. Install the distillation device and heat it for atmospheric distillation. The distillate at 180°C is gasoline, the fraction at 180-360°C is diesel, and what remains is engine oil. If it is known that there are no impurities such as gasoline and diesel in the waste engine oil, this step can be omitted.

- Pickling

Put the settled and distilled engine oil into a large beaker, heat it to 35°C, and slowly add concentrated sulfuric acid which accounts for about 6-8% of the engine oil volume under stirring (the addition is complete within 30 minutes). At this time, the concentrated sulfuric acid undergoes a sulfonation reaction with the gums and pitch-like impurities in the waste engine oil. To remove these sulfonated impurities, a 10% caustic soda solution which accounts for 1% of the oil volume is added to act as a coagulant and accelerate the separation of impurities. After adding alkali, stir for 5 minutes and let it stand for a period of time. There will be obvious stratification, the upper layer of oil is yellow-green, and there are no black particles and other impurities.

- Alkaline Washing

This step is to remove the organic acid in the waste engine oil and neutralize the residual sulfuric acid during pickling. Put the acid-washed oil into another beaker, heat it to 90°C, slowly add sodium carbonate powder, which accounts for 5% of the oil’s mass under stirring, and check the acidity and alkalinity of the oil after 20 minutes. Take two test tubes, add 1 mL of distilled water to each, add 2 drops of phenolphthalein reagent to one of them, and 2 drops of methyl orange reagent to the other. Then add 1 mL of the oil sample into the two test tubes and shake for 3 minutes. If the color of the aqueous solution layer in the two test tubes does not change, it means that the oil is neutral and the oil should become clear.

- Filter

Industrial use oil filter to filter. Household oil can be filtered 2 to 4 times with 4 to 6 layers of silk cloth to obtain qualified oil.

If you know the various impurities in the waste engine oil, you can adjust the above operation steps according to the actual situation. For example, if the engine oil contains only solid impurities such as metal chips, it can be separated by sedimentation. If only gasoline, diesel, and other substances are mixed into the engine oil, regenerated engine oil can be obtained as long as it is distilled. If only the engine oil is oxidized and deteriorated, it is enough to remove impurities such as organic acids by pickling or alkaline washing.

Professional Oil Recovery Machine

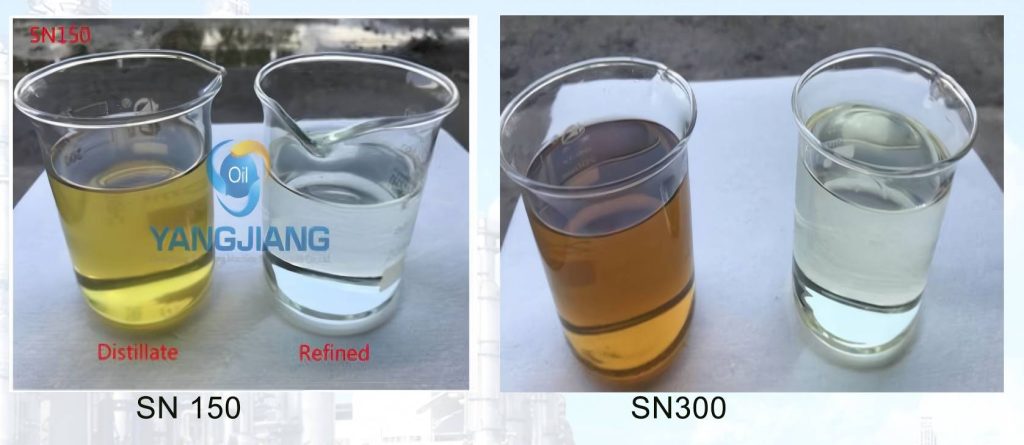

For companies that consume a lot of oil, a large amount of waste oil needs to be recycled and reused, so the help of a professional oil recovery machine is needed. And to obtain cleaner oil that meets higher standards, more processing steps need to be performed. Such as re-purification and re-refining. The re-refining process is currently the main process for the treatment of industrial waste oil. With the continuous development of refining technology, many newer treatment processes have been derived, such as molecular distillation and deep hydroprocessing, which greatly improves the quality of waste oil regenerated products, and can even reach the quality of new oil.