The waste engine oil can be recycled as a lubricant. Engine oil becomes contaminated over time and through heavy use. Contaminants such as dirt, chemicals, and water can get in and degrade the oil. Used Engine Oil Recycling System helps industry recondition oil for reuse in factories and machines. This saves customers the cost of buying new oil. Some industries use cascading lubrication, where spent high-quality motor oils are used reconditioned and used in applications that require lower quality oils.

This can go through several steps before oil loses its usability. Car oil can be collected and recycled to produce reconditioned oil. That oil is cheaper than new synthetic oil and can provide similar protection for engines.

The Purpose of Engine Oil Filtration System

The Used Engine Oil Recycling System can recover waste black motor oil, waste engine oil, transmission oil, ship engine oil, used industry oil, hydraulic oil, transformer oil, etc. to get the clean base oil. This system protects the environment by recycling and re-refining waste oil into pure base oil and diesel. The machine could help users to cut maintenance costs greatly, extend equipment life and significantly reduce waste oil disposal problems.

The engine oil filtration system is widely used to regenerate waste oil, waste industrial lubricant oil, waste hydraulic oil, waste diesel, and waste gasoline, etc. It is applied with vacuum distillation technology, which can renew all the waste oil into based oil, with features of low cost, high recovery up to 85%, and environmental and energy-saving. Waste lubricant oil recycling is not only renewed the waste oil but also reduces the pollutants. Used engine oil recycling is a problem that many companies often ignore. If the waste oil is recycled and then processed and used again, it will be a good cost-saving method.

Product Advantage of the Used Engine Oil Recycling System

Of course, we need to know the advantages of the used engine oil recovery system. In other words, how can it help enterprises?

- The engine oil filtration system is easy to operate and its operating cost is low.

- The equipment is environmentally friendly. The yellow base oil produced by the equipment has no impurities and the waste residue has no secondary pollution to the environment.

- The machine can recover gasoline, diesel oil, oil, rubber oil, and other lubricating oil cleaning oil.

- The refined oil has the characteristic of high quality and there are no discoloration and no odor in the oil.

- The machine has the advantage of low cost. Used Engine Oil recycling system just uses catalyst chemicals, and it costs less than $30 to extract a ton of waste oil. The machine recycles 105 kilojoules of waste oil per ton. The machine USES 40 kilowatts of electricity to recycle a ton of waste oil.

- The factory can be highly automated and integrated. Advanced technology will bring about an improvement in the production rate.

Residue treatment

The waste oil recovery system not only pursues the purification and reuse of waste oil but also needs to prevent the waste generated during the operation of the waste oil recovery system from polluting the environment again. Usually, in the waste oil recycling system, three types of waste materials are generated: exhaust gas, wastewater, and waste residual. The waste oil recovery system fully takes into account the treatment of these wastes. The last link in this system is the treatment of the generated wastes.

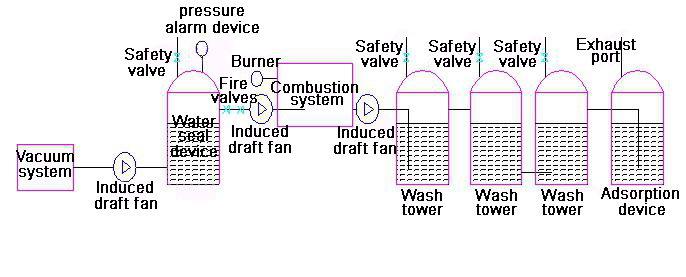

Gas Disposal System

Usually, the gas treatment plant can treat the exhaust gas, and then the treated gas can be returned to the burner to preheat the oil. The specific disposal steps are as follows.

- The non-condensable gas is removed by vacuum unit, and be led into a water seal device by an induced draft fan system; Then it is led into gas combustion system via double fire valves by the induced draft fan system. the double fire valve can effectively prevent tempering goes into the vacuum system. To double strengthen the safety of the equipment, we equip the system with another water seal device, the device uses water to stop the tempering goes into the vacuum system. The water seal device is equipped with a pressure relief valve. When certain pressure is produced, the relief valve will open in time, and a pressure safety warning device will start the alarm.

- The non-condensable gas will be fully combusted after entering the combustion system, and the main components after combustion are sulfur dioxide, nitrogen oxides, black smoke, and water vapor.

- After the combustion system, the gas is led into a three-stage washing tower by an induced draft fan. The washing tower can remove the particulate matter, and most of the sulfur dioxide, nitrogen oxides, and black smoke in the gas.

- The cleaned gas still contains a small amount of sulfur dioxide, nitrogen oxides, and flue gas, which will enter the adsorption system for purification. The purified gas can fully meet the emission standard.

Waste Water

After the waste oil is distilled, about 1%-2% of the water is discharged. Depending on your waste oil, you can send the water to a water treatment company.

Waste Residual

At the same time, about 7% of the residue is discharged, creating a residue discharge system, which can easily discharge the residue at the bottom of the distillation kettle. The residue must be discharged after each batch is completed, otherwise, the residue will become solid and block the pipeline. The temperature will drop.

And the residue can be mixed with diesel about 3:7 and used as heavy oil or asphalt and brake material.

These exhaust gases, liquids, and residues will be collected and stored by specific machines in the waste oil recovery system without causing leakage. Perfect protection of the environment.

YANGJIANG Machine Manufacture Co., Ltd. has unique technology and rich experience in the used engine oil recycling industry and can provide excellent waste oil recycling machines and complete waste oil recycling systems. Of course, we can also tailor a new system that suits your needs based on customer needs.