Product Description

API Group II Base Oil Re-refining Plant can refine all kinds of recycled base oil, vacuum side streams, acid-refined oil, black diesel oil, waste hydraulic oil, waste transformer oil, and all kinds of waste mineral oil that don’t contain solid particles to new oil, with water color. The viscosity, viscosity index, acid value, carbon residue, demulsification value, pour point, and saturated hydrocarbon of refined base oil can reach or close to the API II standard, like hydrogenated base oil. Also, it can reduce sulfur from diesel oil to less than 50 ppm.

Why We Develop API Group II Base Oil Re-refining Plant?

- With the higher and higher requirement on base oil quality of downstream petrochemical enterprises, especially the base oil blending factories, with some old-fashioned technology, the recycled base oil quality is hard to meet the requirements of the downstream user. Before the expensive and technologically complex hydrogenation technology is widely used in oil recycling factory, there are many re-refining technologies, such as fuming sulphuric acid refining technology, lewis acid refining technology, this technology is better than the old fashioned technology, but there’s still a big gap from hydrogenation technology, the environmental pollution problem, the acid sludge, waste white clay disposal are big problems.

- With the strict policy of the National Environmental Protection Department, many many unqualified small oil recycling and oil refining factories were closed by the government. So now, the market requires a kind of efficient, low processing cost, environmentally friendly, and pollution-free refining process.

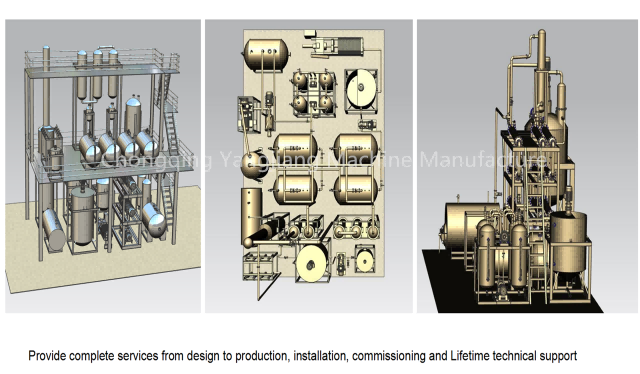

So, YANGJIANG invested a lot of money and manpower to develop this type of environmental protection, energy-saving refining equipment YJ-SR series machine.

Technical Parameter of Solvent Recycling Equipment

| Model | Unit | YJ-SR-5 | YJ-SR-10 | YJ-SR-15 | YJ-SR-20 | YJ-SR-30 | YJ-SR-50 | YJ-SR-100 |

| loss | 1-2% | |||||||

| Temperature range | 0-130C | |||||||

| capacity | Ton/DAY | 5 | 10 | 15 | 20 | 30 | 50 | 100 |

| Total power | KW | 24 | 47 | 50 | 65 | 70 | 85 | 165 |

| Noise | dbA | 45 | 65 | 65 | 70 | 70 | 75 | 75 |

| Dimension | MM | 7500 | 10000 | 11000 | 12000 | 13000 | 20000 | 35000 |

| 3500 | 5000 | 5000 | 6000 | 7500 | 9000 | 16000 | ||

| 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 10000 | ||

| Weight | TON | 7 | 9 | 15 | 18 | 23 | 30 | 47.5 |

| 1*40 | 1*40+1*20 | 2*40 | 2*40HQ | 3*40 | 3*40+1*20 | 5*40 | ||

| Recommended plant area | square meter | 150 | 270 | 350 | 400 | 600 | 1000 | 2000 |

What the Difference Between Our Solvent Refining Machine and Other Company’s Solvent Refining?

- Our solvent can be recovered and reused, again and again, unlike the furfural solvent, which always needs to change solvents.

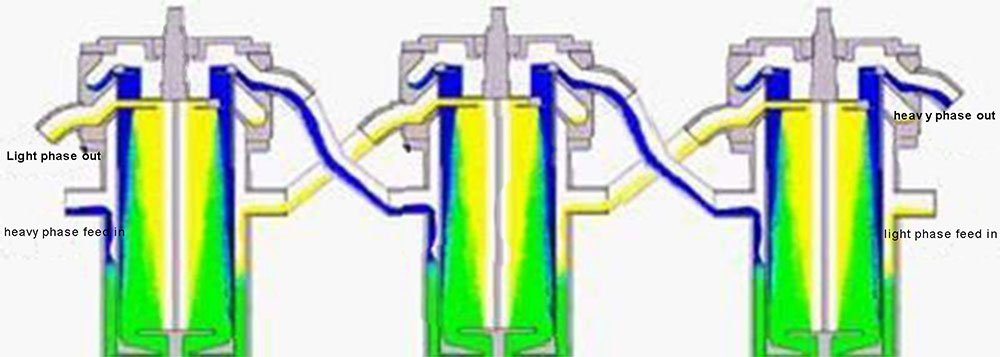

- Other companies use an extraction tower or rotary towers for solvent refining, but we use centrifugal extraction for refining.

- Our solvent is a self-developed composite additive, not Single additive.

- The general solvent refining can only get the oil with a color standard of 1.0. Our solvent refining can get the oil with the color standard of 0.1.

Advantages of Multifunctional Solvent Extraction Machine

- Wide Application and High Quality: The multifunctional solvent extraction machine has a wide application, which can process all types of mineral oils without solid impurities to brand new high-quality oil. The refined oil is water-white with a color number less than 0.1, and all performance indexes reach API II hydrogenated base oil.

- Low Oil Loss: The equipment offers low oil loss compared to traditional refining processes. Its unique structure is capable of selectively removing the impurities such as sulfides, oxides, colloids, and asphalt that may affect the performance of the base oil. For example, when base oil is vacuum-distilled, oil loss is only 0.8–2%, while for diesel oil, loss is only 1–1.5%.

- Strength Material and Low Cost: Constructed with SS#304 stainless steel material, the machine is corrosion-proof and durable. Its refining cost is very low: refining one ton of base oil costs approximately 200 RMB (approximately 30 USD), and one ton of diesel oil costs approximately 150 RMB (approximately 23 USD), much lower than hydrogenation or Lewis acid refining technology.

- Eco-Friendly Process: The process is eco-friendly with no pollution. It emits no waste gas, wastewater, or sludge, and neither does it require oxidizing agents, chemicals, catalysts, white clay, nor any filtering agents such as silica gel, filter paper, or filter cloth.

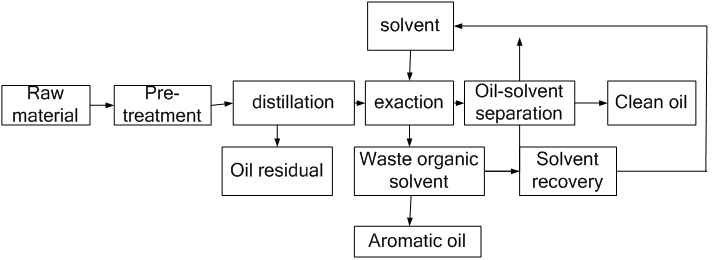

The Process of Multifunctional Solvent Extraction Machine

How the Solvent React with the Oil?

The solvent and oil are two immiscible solutions, both two immiscible solutions of different densities are pumped into the extractor through two entrances respectively, and then rapidly mixed in the gap between the drum and the shell, and the mixed liquid enters the drum through the inlet at the bottom of the drum, and the accelerated heavy phase is thrown to the lateral side of the drum. the light phase remains on the inside of the heavy phase, the two-phase interface is between the light phase outlet and the heavy phase underflow channel, and the heavy phase underflow channel is in the upper part of the separation zone composed of heavy phase enthalpy.

FAQ

Yangjiang has been committed to solving various waste oil purification problems,in addition to the above waste oil recycling plants, we also provide other used oil re-refining plants, such as Used Oil to Base Oil Plant, Waste Oil to Diesel Oil Distillation Plant,Diesel Desulfurization Machine,Base Oil Blending Plant,Transformer Oil Regeneration Machine