Waste oil comes from different places, such as 4S shops, car repair shops and so on. Accumulating waste oil little by little will get a lot of waste oil. If it is discarded or burned, it will cause irreversible harm to the environment. If the waste oil distillation machine is used to recycle the waste oil, the cost of oil will be saved, and the recovered waste oil can be used again.

Before using used oil distillation plant to treat waste oil, it is necessary to treat the waste oil first. Because waste oil contains a large number of mechanical impurities, heavy metals, colloids, moisture, metal ions, and other impurities, in traditional kettle distillation or new tube distillation, tower distillation, thin film distillation, and even molecular distillation, heat exchange It is very easy to form heavy oil coking and fouling on pipes and pipe walls such as heat sinks, and the uneven heat conduction and heating also exacerbate the formation of coking and plugging. Affected the quality of line oil, and the shutdown caused the production progress and increased the cost of maintenance. Then at this time, it is necessary to add a pretreatment agent for the distillation of waste oil to the waste oil.

The oil additives that need to be used before using the oil distillation unit are generally: flocculant and decolorant.

The role of flocculants is: to settle mechanical impurities, heavy metals, colloids, water, metal ions, etc. in the oil, preventing coking and scaling in the subsequent distillation process, uneven heat conduction, and uneven heating will exacerbate coking and block pipes. The formation and the impact on the quality of line oil, further causing the shutdown of the furnace affects the production schedule, increasing the cost of maintenance.

The role of decoloring and deodorizing agents: oil contains sulfur, nitrogen, heavy metals, oxides, phosphorus, chlorine and other impurity atoms, which will cause oils containing hydrocarbons to show different colors and affect the stability of the oil.

Working principle of oil distillation machine

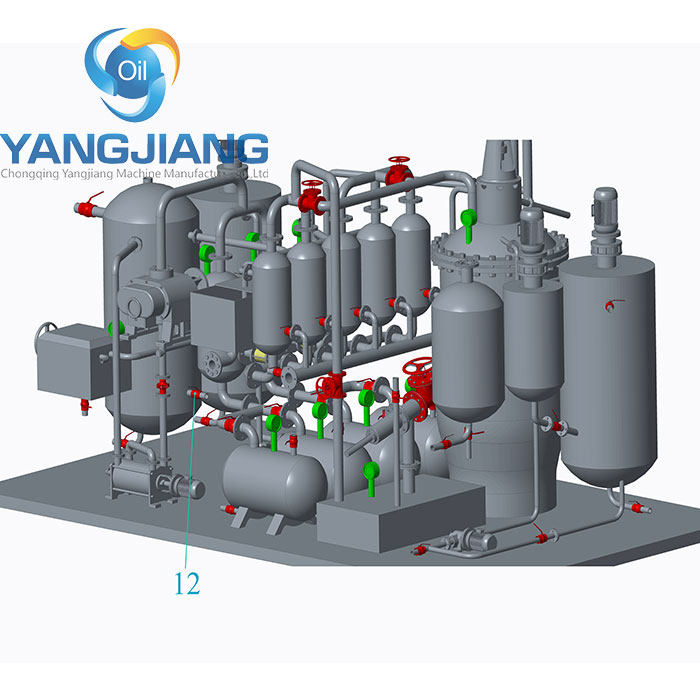

After years of unremitting efforts by the R & D team, Yangjiang has already possessed a complete and mature waste oil distillation technology. Vacuum distillation is the core waste oil regeneration technology. The regeneration and reduction system produced by Yangjiang uses batch processing to treat pretreated waste oil, that is, by natural sedimentation, or by using centrifuges to remove water and magazines. After entering the catalyst reaction tank, stir the reaction thoroughly. The fully reacted waste oil is pumped into a distillation kettle, and the waste engine oil is heated under a vacuum. As the temperature rises, the oil and gas of different components will evaporate. After cooling, the corresponding fuel oil, light base oil, and heavy base oil can be obtained. The liquefiable part can be reused. The non-liquefiable part enters the heating system for combustion through the gas system without wasting any resources.

The light oil processed by the waste oil distillation machine can be added to tractors, ships, and generators for reuse. Heavy oils also have different uses. Both the light base oil and heavy base oil produced meet the reuse standards. The gas is burned, and the solid obtained after the distillation is asphalt, which can be used for paving roads, waterproofing buildings, and so on.

What kind of waste oil can the oil distillation machine handle?

There are different types of waste oil, and the general consumer may think that one oil distillation plant can only handle one type of waste oil accordingly. But what I want to tell you is that a kind of oil distillation machine is not only able to handle only one kind of waste oil. It is possible that the scope of use of oil distillation equipment produced by other manufacturers is very limited. However, the equipment produced by Yangjiang can handle many types of waste oil. The types of waste oil include waste lubricating oil, waste engine oil, pyrolysis oil, and tire pyrolysis oil. Buying an oil distillation device can handle multiple varieties of oil, which saves the purchase cost of the machine.

Recommended oil distillation machine brands

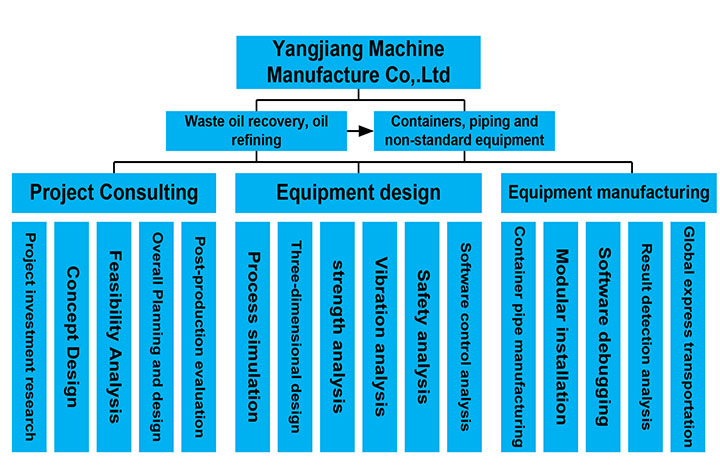

In China, there are countless manufacturers of oil distillation equipment, and in Chongqing alone, there are more than 100 of the more famous manufacturers of waste oil distillation units. Whether it is buying large machinery or small equipment, low prices and high production efficiency are the most valued qualities for customers. And Yangjiang can perfectly meet these requirements. Yangjiang Machinery Manufacturing Co., Ltd. is one of the more famous manufacturers of oil distillation machines. It is located in Chongqing Heavy Industry Production Zone, that is Jiulongpo District. Yangjiang has an excellent professional independent research and development team to design and manufacture oil distillation units. In addition, Yangjiang also has its own manufacturing plant to produce oil distillation machines. This equipment is a factory direct sale, the quality is guaranteed and the price is low, which is worth buying by consumers.

We have introduced a lot of details about the oil distillation machine, if you have any questions, please feel free to contact us. For more details, please visit the Yangjiang website. www.oilrecyclingplant.com