Waste oil to diesel conversion has emerged as a lucrative opportunity for small businesses worldwide, but is it profitable? In this article we’ll examine the process of turning waste oil into diesel, its profitability analysis and provide steps on how you can start your own waste oil to diesel project.

What is Waste Oil Recycling?

Waste oil recycling involves collecting and reprocessing used oils – such as cooking oil, motor oil or industrial lubricants – into usable products such as diesel fuel. Instead of disposing of them as waste products that could harm the environment, recycling transforms them into valuable resources that provide useful uses such as diesel fuel for heating homes or powering cars.

Used oils are produced by various industries, including automotive, food service and manufacturing. If disposed of improperly they pose environmental risks that must be managed. Recycling can help not only mitigate those risks but also decrease virgin oil extraction requirements.

Recycling waste oil typically involves filtering out impurities, treating it for contaminants removal, and turning it back into usable fuel or products. Recycling can significantly lower disposal costs while creating revenue streams and contributing towards sustainability goals for businesses.

Waste oil recycling plays an essential part in supporting a circular economy and decreasing fossil fuel dependency. Small businesses have an opportunity to contribute to environmental conservation while enjoying economic benefits as part of this practice.

The Process of Converting Waste Oil to Diesel

Converting waste oil to diesel involves multiple steps and processes that transform used oils such as cooking oil, motor oil, or industrial lubricants into usable and eco-friendly fuel sources. Here is an outline of this process:

- Collection and Filtration

The initial step involves collecting waste oil from various sources such as restaurants, automotive workshop,s or manufacturing facilities. After collection, this oil must then undergo filtration to remove solid impurities like food particles, dirt particles and metal shavings before proceeding further with processing. Taking this extra step ensures that future treatment processes will produce high-grade oil suitable for further use.

- Pre-Treatment

Once filtered, waste oil needs to be pre-treated in order to eliminate water, acids, and other contaminants that have contaminated it. Usually this involves heating or chemical treatments which neutralize free fatty acids before it goes through conversion process – this ensures its quality as diesel product in the end product.

3. Conversion

Once oil has been thoroughly cleaned and pre-treated, one of two primary methods is used to convert it to diesel:

- Transesterification: This chemical process entails reacting waste oil with an alcohol (such as methanol) and catalyst ( such as sodium hydroxide) to produce biodiesel fuel for use in diesel engines without modifications required to run cleaner-burning biofuel engines.

- Pyrolysis: Pyrolysis, or thermal decomposition, involves heating waste oil to high temperatures without oxygen present, in order to break it down into smaller molecules and create diesel-like fuel. Pyrolysis is especially useful for processing more complex oils such as industrial lubricants.

4. Purification

Once converted fuel has been produced, any remaining impurities or byproducts must be purified so as to meet industry standards and be safe for engine use. Purification may involve distillation, filtration or chemical treatments.

5. Testing and Quality Control

Before diesel can be put to use, it must go through rigorous quality controls to ensure it satisfies fuel standards. Parameters like viscosity, flash point and sulfur content are measured to ensure optimal performance as well as compliance with environmental regulations.

6. Distribution or Utilization

Businesses have various options when it comes to using or distributing the finished product. Businesses could opt for:

- Diesel can be used for various uses within their operations (e.g. powering vehicles and machinery).

- Sell it directly to local markets such as transportation companies and agricultural businesses.

- Combine it with traditional diesel to create a more eco-friendly fuel mix.

Converting waste oil to diesel not only provides an economical means of disposing of it but also serves as a valuable resource that reduces dependency on fossil fuels. Converting waste oil to fuel can contribute to creating a circular economy while simultaneously generating revenue and lessening their environmental footprint.

Is Waste Oil to Diesel Profitable?

Small businesses exploring sustainable energy ventures often face the question of the profitability of turning waste oil into diesel for fuel production. While the potential profit exists, its actualisation depends on several factors including market conditions, operational efficiency and regulatory support. Let’s break it down from various angles to understand if this business model can bring financial returns.

Cost of Raw Materials

One of the primary advantages of waste oil-to-diesel conversion is the low cost of raw materials. Waste oil, including used cooking oil or industrial lubricants, can often be seen as a liability by businesses producing it; many restaurants, automotive shops and manufacturing facilities pay to dispose of their waste oil voluntarily allowing recyclers to acquire it at minimal costs – further improving profitability through reduced production expenses and expense.

Market Demand for Diesel

Diesel is an essential energy source in industries including transportation, agriculture and construction, providing a steady market for recycled diesel fuel production by small businesses. Local fleets or farms could purchase recycled fuel produced locally; even using it themselves reduces their dependence on traditional suppliers of fuel.

Operational Costs and Efficiency

A successful waste oil to diesel conversion project relies heavily on its operational efficiency. Equipment, labor and energy requirements for conversion may differ dramatically between operations of various sizes; smaller operations may find modular machines more economical but reliable in producing high quality diesel.

Environmental and Social Benefits

While not directly tied to financial profits, waste oil-to-diesel conversion provides environmental and social advantages that indirectly increase profitability. By recycling waste oil instead of disposing it in landfills, businesses reduce landfill waste while lowering carbon emissions – two benefits which enhance their reputation while drawing eco-conscious customers in.

Waste oil-to-diesel conversion can be profitable for small businesses with careful planning and execution, though success depends on careful decision-making and execution. While challenges such as equipment costs and regulatory compliance exist, its long-term financial and environmental advantages make this an attractive opportunity for entrepreneurs looking to invest in energy’s future.

Steps to Start a Waste Oil to Diesel Project

Starting a waste oil-to-diesel project takes strategic planning and execution. Here is a concise guide that can help get you underway:

- Market Research: Locate reliable sources for waste oil such as restaurants, auto repair shops or manufacturing units. Conduct an in-depth examination of local diesel demand so as to guarantee an ample marketplace for your product.

- Calculate Your Startup Costs and Secure Funding: Assess all startup expenses such as equipment, labor and permits before investigating funding options such as government grants, loans or private investors to cover initial expenses.

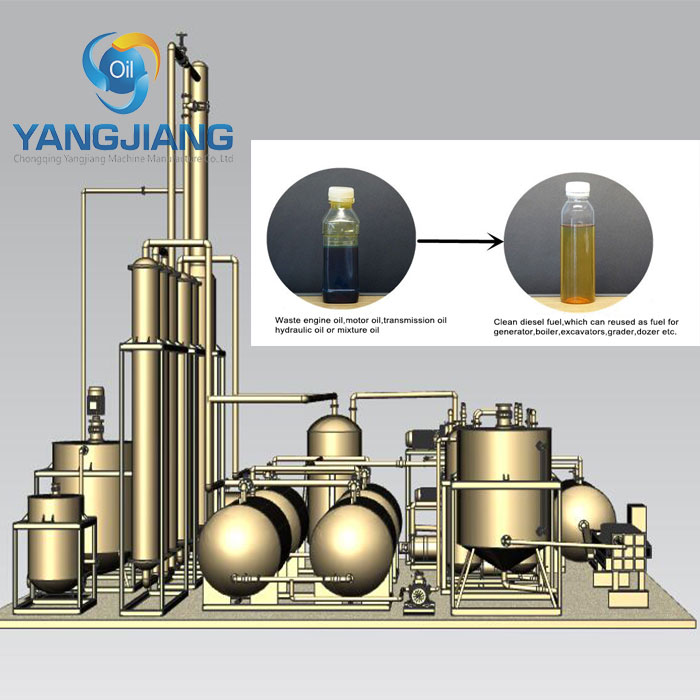

- Choose the Appropriate Equipment: For efficient and compliant operations, invest in a high-quality waste oil to diesel machine suited to the size and scale of production. Be sure it meets all safety and environmental regulations to maximize efficiency and compliance.

- Acquire Necessary Permits: Review local regulations concerning waste oil recycling and fuel production, then secure all required licenses and permits to ensure legal operation and avoid fines.

- Create a Collection System: Partner with local businesses to collect their waste oil, and ensure a steady supply chain that feeds into your operations.

- Beginning Production and Distribution: Convert your waste oil to diesel, and explore sales channels. Sell directly to local industries or fleets, or blend it with traditional diesel for wider market appeal.

By following these steps, small businesses can capitalize on the growing need for sustainable fuel, turning waste into an opportunity for profit.

Is Waste Oil to Diesel Machine Worth to Invest

Investment in a waste oil-to-diesel machine can be an ideal solution for small businesses, yet it is crucial that they carefully evaluate both its advantages and potential drawbacks. On one side, these machines provide low operating costs since waste oil can often be obtained for free or at highly reduced rates – thus increasing profit margins significantly. Furthermore, these machines often deliver an impressive return on investment (ROI) over time with consistent production and efficient management practices; additionally, they align with sustainability initiatives by cutting carbon emissions, further strengthening a company’s brand recognition while increasing customer attraction.

Small businesses with access to an adequate source of waste oil and a consistent market for diesel may find investing in a waste oil-to-diesel machine an efficient and sustainable decision.

If you have any need,please feel free to contact YANGJING.

Recommended Products