Demand for lubricants worldwide continues to increase due to industries like automotive, manufacturing and aviation. Due to increasing environmental concerns and sustainable practices, refining used lube oil has emerged as an innovative and cost-cutting solution. In this article we explore this journey of turning used oil into premium lubricants using advanced refineries processes.

The Hidden Potential in Used Lube Oil

Used lube oil may seem like a waste, but its potential is undeniable and could transform the lubricant industry. When refined properly, used oil can be transformed into high-grade base oils that rival those produced from virgin crude. Not only does this reduce extraction needs; but also it addresses environmental challenges by preventing improper disposal which could cause soil and water contamination.

Refining used lube oil is an integral component of the circular economy, turning something once considered waste into an invaluable resource. Through advanced technologies we are now able to recover up to 90% of original oil, meeting stringent industry standards while helping cut emissions, conserve natural resources, and decrease our ecological footprint significantly.

Used lube oil refining represents a win-win solution in today’s increasingly sustainable world, providing economic benefits while simultaneously protecting the environment. It stands as an invaluable way of greener, more cost-efficient industrial practices.

Before Refining: Collection and Pre-Treatment

The transformation of used lube oil to premium lubricants begins long before reaching a refinery. It starts with gathering it from various sources such as auto repair shops, industrial facilities, and recycling centers before being pretreated with various pre-refining treatments designed to remove impurities that might hinder the refinement process or compromise the quality of the final product.

- Filtration: The first step involves filtering used oil to remove large particles, debris, and any solid contaminants so that only liquid oil progresses forward in the process.

- Dehydration: Used oil often contains water that needs to be extracted to ensure successful refining processes. Dehydration can typically be accomplished using heat or vacuum distillation processes which effectively separate water from its oil constituents.

- Demetallization: Metal contaminants like lead, copper, and iron can accumulate in used oil due to engine wear and tear, leading to demetallization processes like chemical treatments or centrifugation being utilized to eliminate these metal traces from entering our bodies.

Pre-treatment of used oil is an essential step that ensures it will be suitable for refining. By extracting water, solids, and metals from it prior to refining, pre-treatment not only increases the efficiency of refining but also extends the equipment’s lifespan while improving product quality.

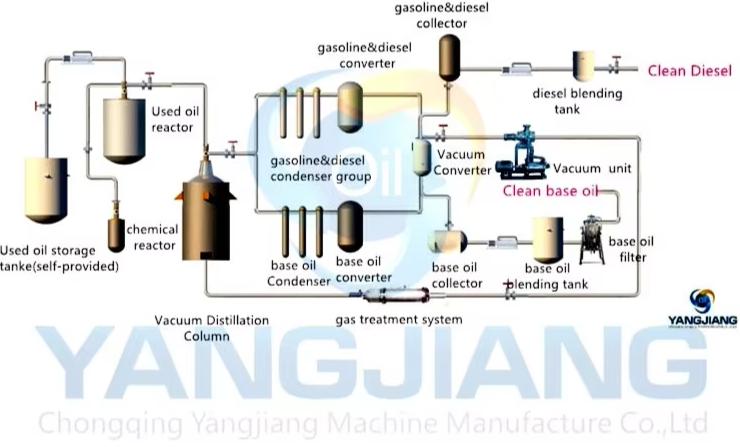

Key Lube Oil Refining Processes

The refining process is central to turning used lube oil into high-grade base oils suitable for premium lubricants, using advanced techniques designed to remove impurities, enhance performance, and ensure it conforms with industry standards. Here is an outline of its key steps:

- Distillation: Used oil is heated in a distillation unit to separate its components based on their boiling points, such as lighter hydrocarbons such as fuel oils being removed through distillation while leaving behind heavier base oil – an integral step for isolating usable fractions in an otherwise worthless source of oil.

- Hydrotreating: Hydrotreating involves injecting hydrogen under high pressure and temperature to chemically react with impurities such as sulfur, nitrogen, and oxygen that could compromise oil’s stability, colo,r or overall quality if they accumulate over time, by extracting contaminants that diminish the performance of oil products through this treatment process. Hydrotreating improves its stability, color quality, and overall quality by eliminating contaminants that threaten its performance.

- Solvent Extraction: Solvents are used to selectively dissolve and extract undesirable components such as aromatic compounds that could compromise viscosity or oxidation resistance in refined oil products used in high-performance lubricants, thus assuring they have all necessary properties for use as high-performance lubricants.

- Dewaxing: To maintain fluidity at low temperatures, waxes need to be extracted using solvents or catalytic processes in a process called dewaxing. Ultimately this results in base oils with superior low-temperature performance.

- Final touches: In this final stage, polishing the oil helps ensure it meets stringent quality standards and can be blended with additional additives for additive blending.

Refining processes work collaboratively to transform used lube oil into high-grade base oil that can match up against virgin oils in terms of performance and reliability.

After Refining: Additive Blending and Formulation

Once lube oil has been refined into high-grade base oil, the next key step in its transformation into finished lubricants for specific uses is additive blending and formulation. Here, the base oil is transformed into tailored products to meet modern machinery’s and engines’ performance requirements by carefully choosing and mixing in additives that enhance its performance characteristics.

Viscosity modifiers ensure optimal flow across a range of temperatures, while anti-wear agents protect engine components from friction and wear damage. Detergents and dispersants keep engines clean by preventing sludge and deposit formation while antioxidants extend oil life by decreasing oxidation. Other additives, including corrosion inhibitors and foam suppressants, further boost its reliability and efficiency.

Formulating is a highly precise process, with each additive combined in precise proportions to meet industry standards and performance specifications. No matter if it is for automotive, industrial, or marine use – the end result will always be an exceptional premium lubricant that extends machinery lifespan while cutting maintenance costs.

Benefits of Lube Oil Refining Plant

Investment in a lube oil refining plant brings both businesses and the environment significant advantages. Refining used oil into high-quality lubricants offers businesses a sustainable solution for recycling old oil while conserving natural resources, while cost-cutting virgin base oil production allows businesses to meet market demands more profitably while meeting profitability goals more cost-effectively. Furthermore, owning such a refining plant ensures better quality control allowing tailored production tailored to specific industrial requirements.

When it comes to setting up a lube oil refining plant, YANGJIANG is an acclaimed manufacturer offering advanced refining technologies. Their eco-friendly equipment meets global standards while helping businesses maximize productivity, ensure regulatory compliance, and contribute to a greener future. Investing in our refining plants is a wise move towards sustainability and long-term profitability in the lubricant industry. Reach out now!

Recommended Products