This year, as a professional manufacturer of Solvent Extraction machines, YANGJIANG has developed the new Newest Diesel Desulfurization, Denitrification, and Decolorization Technology. Newest Diesel Desulfurization, Denitrification, and Decolorization Technology—Reduce the sulfur to 10ppm to produce Euro-V standard diesel.

YJ-SNC diesel desulphurization machine can remove sulfur to less than 10ppm, and remove nitrogen from diesel fuel, which contains catalytic cracking distillate diesel fuel, or the diesel from fractionation column, gas oil, or pyrolysis oil. the output oil can reach the Euro VI standard that can be reused for cars directly.

Why explore Diesel Desulfurization, Denitrification, and Decolorization Technology?

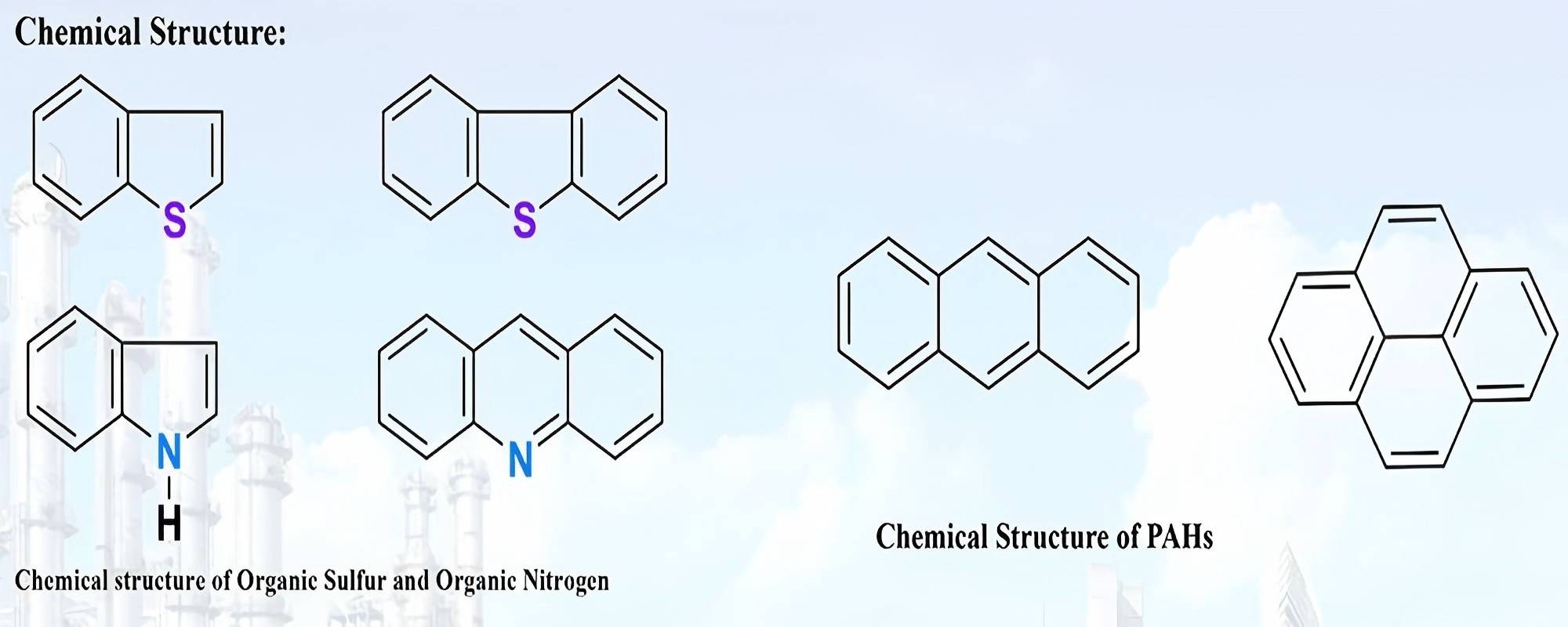

In the process of petroleum refining, diesel oil, gas oil, and fuel oil can be obtained by atmospheric and vacuum distillation and catalytic cracking, which still contain many impurities, such as organic sulfur, organic nitrogen, and PAHs (Polycyclic Aromatic Hydrocarbons), these impurities seriously affect the oil quality. For example, organic sulfur, organic nitrogen in the combustion will lead to serious air pollution, PAHs and organic nitrogen (such as benzopyrene) are easy to polymerization or be oxidized into a colloid, affecting the stability of the oil, resulting in the oil color return back to dark.

With the increasing environmental requirements in recent years, the demand for high-quality oil products is gradually increasing. Catalytic hydrogenation or hydrocracking is currently used in the market to remove sulfur, nitrogen, and other undesirable components from oil. Although hydrogenation technology can treat the above impurities, its high equipment requirements, high temperature and pressure, high project investment, expensive and easily deactivated catalysts, and high processing costs make it difficult to meet the increasing requirements in terms of effectiveness, economy, and safety. Therefore, it is crucial to develop new integrated fuel desulfurization, denitrification, and decolorization technologies with a small investment scale and low operating costs.

From the above Chemical Structure, due to the Organic Sulfur and Organic Nitrogen containing heteroatoms such as S and N, σ- the density of lone pair electrons is higher, so they show strong electronegativity; the PAHs(Polycyclic Aromatic Hydrocarbons) also show a certain electronegativity because of their conjugated π-electron system. Therefore, technology R&D persons can remove impurities from oil by chemical complexation by using chemicals showing positive charge. Through a long period of testing and demonstration, our R&D team finally succeeded in developing a kind of liquid-positive electric extractant suitable for oil desulfurization, denitrogenation, and decolorization.

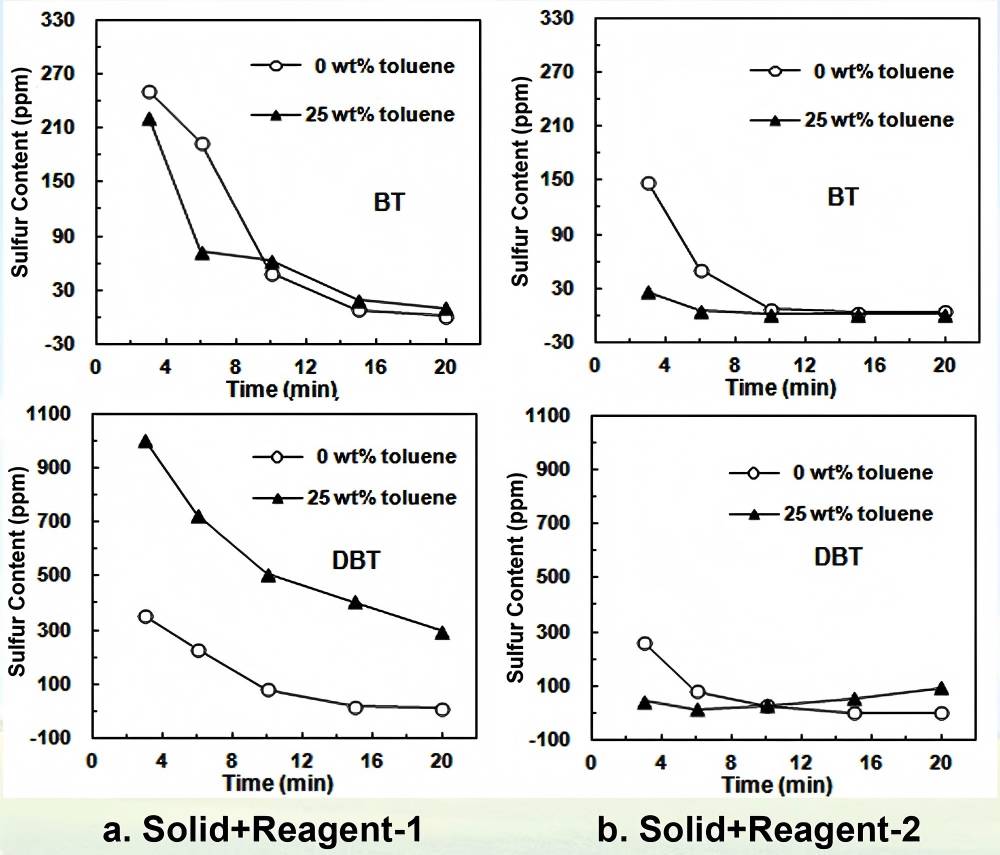

In the past, we usually chose solid desulfurized chemicals, but they only can remove 70% sulfur. Taking thiophene sulfides as an example, there are two main types of chemical structure: (1) σ-Lone Pair Electrons; and (2) π-Electron System(Soft Alkali). However, the usual solid-state positive material can only interact with one type of electron (or interact with the σ-lone pair electrons, or interact with the π-electron system), but can’t interact with the two types of electron at the same time. In addition, Solid desulfurized chemicals also have problems with insufficient exposure to active sites. The above-mentioned problems greatly limit the effectiveness of desulfurization.

YANGJIANG’s R&D team also found that it’s difficult to collect clear and transparent oil due to suspended micron-sized complex particles appearing in the upper oil phase during the desulfurization process, these micron-sized complex particles are difficult to remove, If these complex are destroyed, impurities such as organic sulfur, organic nitrogen, and PAHs will return to the oil and interfere with the desulfurization effect. At the same time, the lower phase complex (residual) is very easy to form a sticky and strong oil-bearing waste sludge, which is seriously sticky to the wall.

In summary, the key to the realization of the integrated technology of desulfurization, denitrogenation, and decolorization lies in two points: 1) liquefying the solid positively charged material and enabling it can interact with the two types of electrons at the same time; 2) solving the problem of micron-sized particles and avoiding produce high viscosity residue.

what is this new technology about Solvent Extraction?

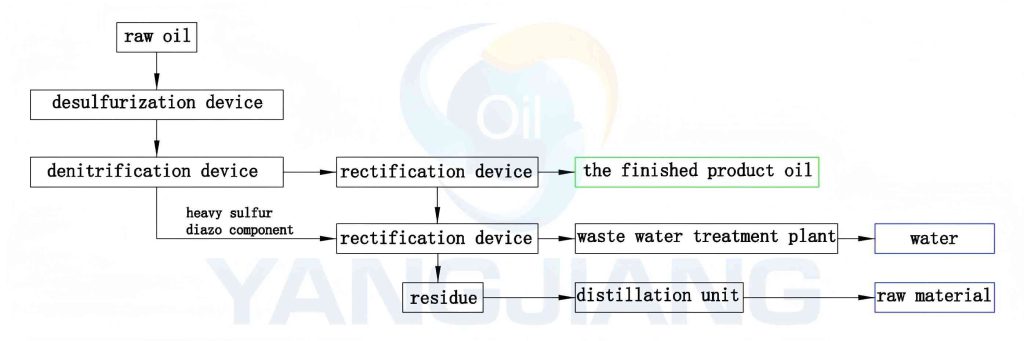

YANGJIANG’s Newest Diesel Desulfurization, Denitrification, and Decolorization Technology is the use of liquid chemicals to dissolve the solid positive substances in this technology to achieve their liquefaction. Liquefying agents have unique plane structural characteristics, which can disperse the positive charge of the solid positive material in the plane, to construct a positive charge structure that can interact with both types of electrons.

As shown in the following figure, the method showed the excellent effect of removing benzothiophene (BT) and dibenzothiophene (DBT) in oil.

How do Diesel Desulfurization, Denitrification, and Decolorization Technology work?

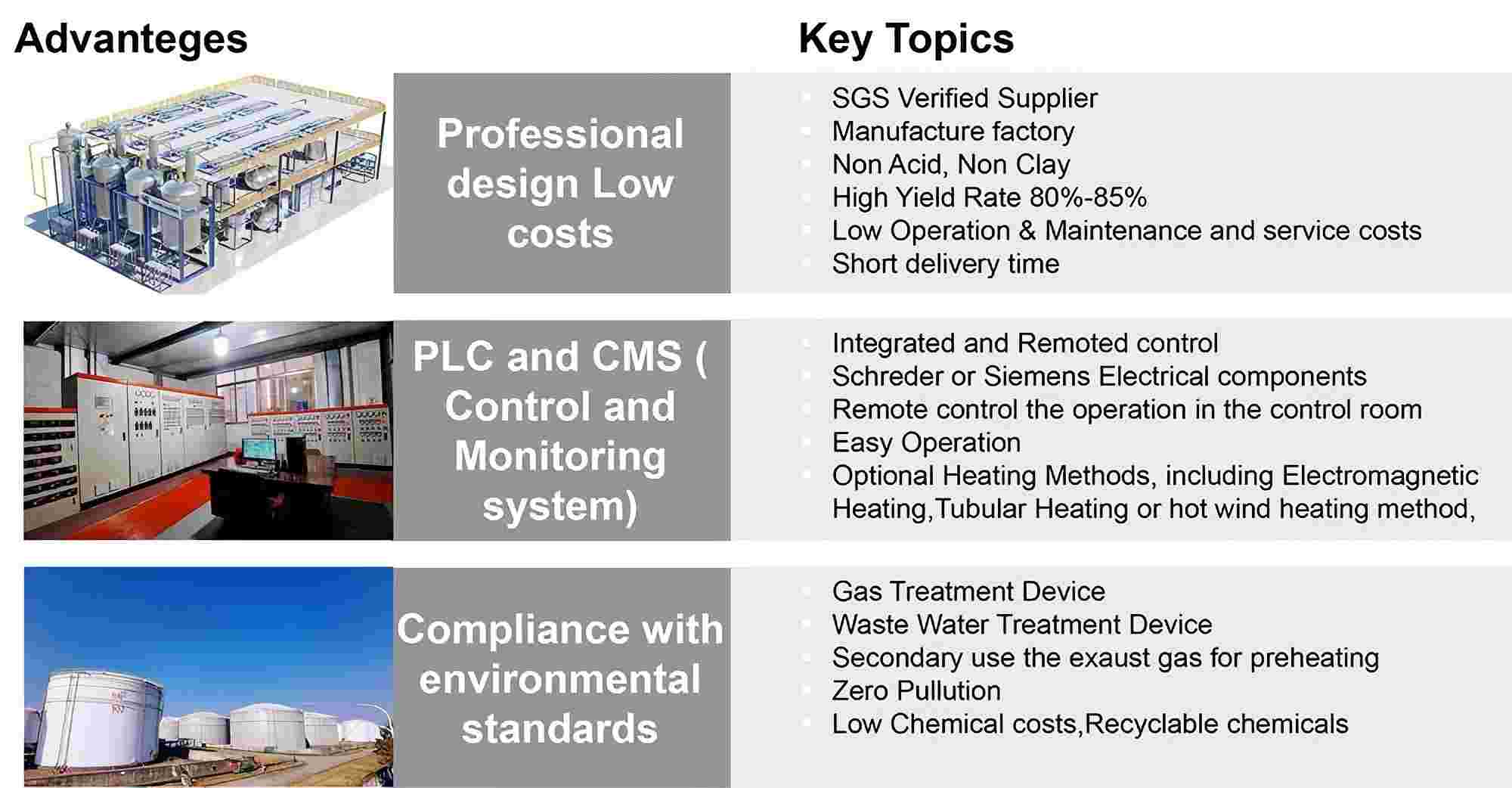

Features and advantages of Solvent Extraction Machine:

- PLC or DCS fully automatic and Continuous process

- With around 0.5% Chemical consumption, the chemical additives can be recovered and reused again and again, and the additive is highly active even at normal pressure and temperature.

- Compared with hydrogenation technology, YANGJIANG’s desulfurization technology has significant advantages in terms of effectiveness, economy, and safety.

- The liquid desulfurization and denitrification chemical can quickly dissolve the suspended solids in the oil to obtain a clear and transparent product oil, which can be recycled indefinitely;

- Zero pollution, No oily residue in the whole process.

- With a 100% recovery rate, the final oil output is essentially split into two parts: light-colored, low-sulfur, and low-nitrogen product oil and dark-colored sulfur-rich and nitrogen-rich oil, with almost no oil loss.

- The sulfur can be reduced to less than 10 ppm, which can meet the Euro 6 standard and can be directly used for cars.

How is a Solvent Extraction Machine Made?

If you are interested in the new Newest Diesel Desulfurization, Denitrification, and Decolorization Technology or Solvent Extraction Machine, please contact us and our team of engineers will answer your questions.