The waste oil treatment process includes cracking waste oil into diesel. The waste oil cracking process requires the use of waste oil recovery machines. The Engine Oil Recycling Machine can easily complete the process of cracking waste oil into diesel. The Yangjiang Engine Oil Recycling Machine is very safe in the waste oil cracking process. The waste oil recovery rate is 93-95%. In addition, the waste oil treatment cost of this machine is low and the design is reasonable. Recycling one ton of waste oil only costs 5 to 6 dollars.

Gasoline and diesel can be obtained through different distillation temperature ranges during the process. 50-160℃ is the temperature range of the gasoline fraction and 160-410℃ is the temperature range of the diesel fraction. After cracking and cooling, about 2-5% of the liquid is gasoline. About 85-90% of the liquid is similar to diesel and can meet the specification of 15 # diesel. They can be used as industrial or civilian fuel or even power-driven fuel. Oil is a small part of diesel oil in the refining industry, they belong to the same molecular weight of different petroleum series, diesel production is very feasible.

Components of Waste Oil Treatment Process:

- The waste oil treatment process has a pretreatment system. It means that the waste oil will be pumped into the distillation kettle after pretreatment.

- The Engine oil recycling machine is equipped with a distillation system. By burning gas, coal, or fuel oil to bring the oil in the kettle to working temperature. The system is equipped with a mixing system and heat preservation system.

- The equipment also has a cooling system. Gaseous hydrocarbon will be cooled to liquid base oil, gasoline, and diesel.

- It has an oil storage system. The base oil from the waste oil treatment program, gasoline, and diesel will be stored by the cooling system here and pumped into storage tanks.

- The vacuum system of the machine meets the technology requirement.

- The plant also has a filtration system. The machine can rapidly filter out mechanical impurities

In the waste base oil, gasoline, and diesel and get the high-quality base oil, gasoline, and diesel.

Advantages of the Waste Oil Treatment Process:

- The waste oil treatment process adopts advanced vacuum distillation technology. Treatment of waste oil does not need an acidic environment and white clay. You only need to add fewer additives which are low cost and easy to buy.

- The operation cost of the machine is very low. It will cost a few dollars to produce a ton of waste oil and then produce a high-quality base oil. The additives are basic chemicals that can be purchased anywhere.

- It is easy to operate equipment and has a low operating cost. Only one or two workers are needed to operate the machine.

- It can pyrolysis waste oil and many kinds of used engine oil into diesel oil. After pyrolysis, diesel oil can be used for the industrial and home application, and even used for diesel engine

- It is an environmentally friendly machine. In the whole process, the machine goes through the sealing process. The waste gas is discharged by the emission standard and will not pollute the environment. Waste residue from waste oil treatment can be used as fuel. No harmful substances were expelled.

- The machine has the feature of a high recovery rate.

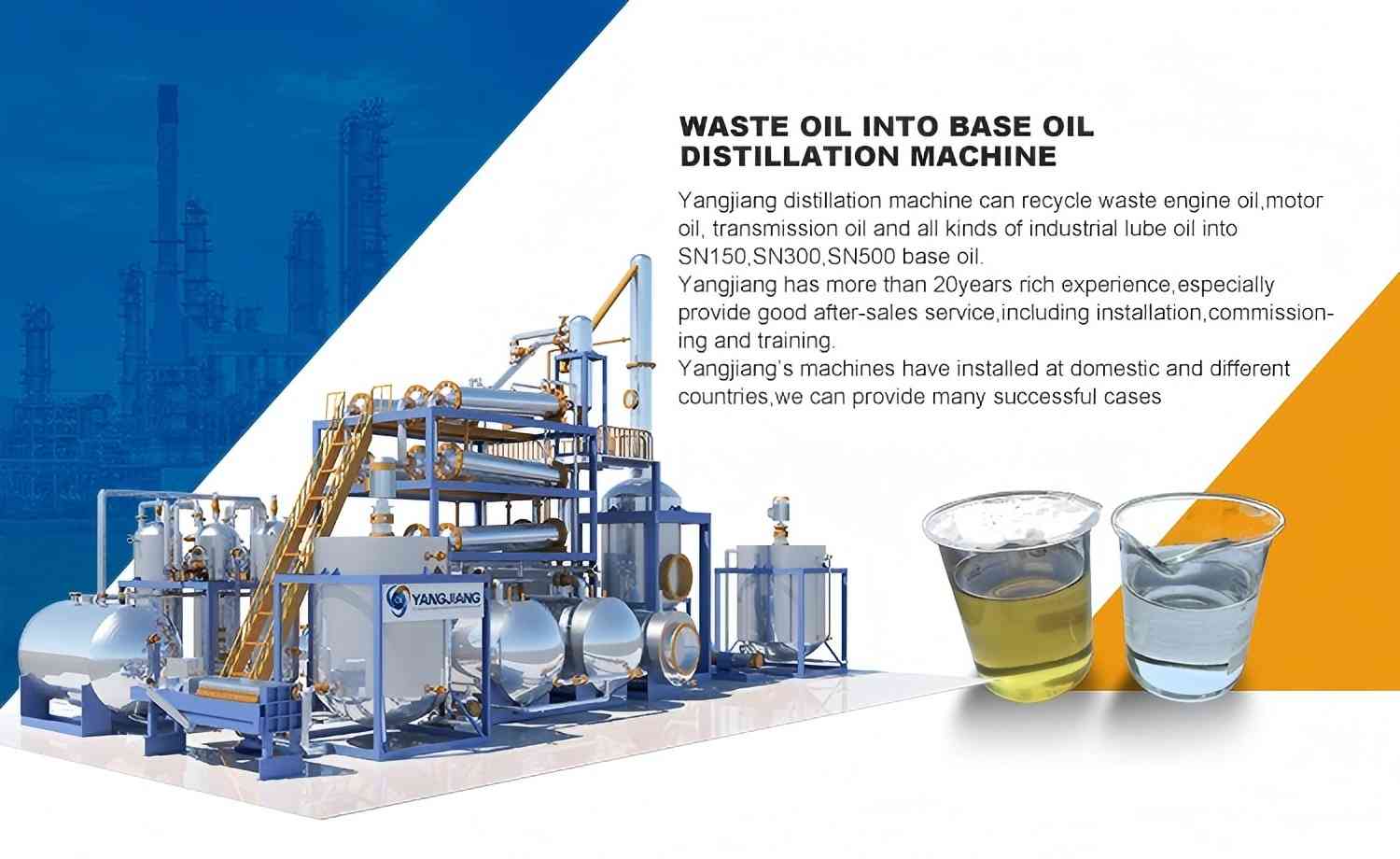

Because waste oil processing and recycling require strict implementation of every step, it is most important to choose excellent Engine Oil Recycling. If you are looking for a reliable Engine Oil Recycling Machine (waste oil recovery machine)? We recommend YANGJIANG‘s waste oil recovery machine. The waste oil recovery machine produced by Yangjiang uses the best parts and is cheaper than the waste oil recovery machine produced by other competitors in the market. Yangjiang production of waste oil recovery machines is worthy of consumer trust.