As a necessary supplement for automobiles and diesel vehicles, engine oil has a life span that is not unlimited. After the oil has been used for some time, we all need to replace the car with new oil. Then there is a problem. What to do with waste engine oil? Discard the oil? Doing so will pollute our environment. There is another way to solve the problem of waste oil disposal. That is, the waste oil recycling machine is used to reprocess the waste oil so that the oil can be used again.

How to Detect the Engine Oil?

Generally speaking, the car needs engine oil to keep running. The engine oil can play the role of lubrication and wear reduction for the engine. In addition, it can also play the role of auxiliary cooling, sealing and leakproof, shock absorption, and buffer for the car. The engine of the vehicle can’t reach peak performance without engine oil. That is to say, the engine oil is the blood of the cars. When the oil becomes dirty, the oil recycling machine is required to perform oil treatment to restore its performance.

While the engine oil may mix with impurities such as metal debris or moisture after long-term use. Then the color of the engine oil may turn black. And if the car continues to use black oil, the oil may cause damage to the parts of the engine. So it is essential to check the engine oil to ensure the best performance. The ways to check the engine oil are as follows.

- Make sure the engine isn’t hot. You may burn yourself if you handle engine parts right after you turn off your car. You need to wait at least 10 minutes or plan to check your oil while the engine is cold. A cool engine ensures that the oil has enough time to settle at the bottom of the oil pan and will give you a more accurate reading of how much oil is in the car.

- Open the hood of the vehicle. Most cars have an interior hood-popping lever located under the steering column. Find the interior and pull the lever, then walk to the front of your car and unlatch the hood. Raise the hood so that it is completely open, and prop it up with a metal prop if your car has one. You need to make sure the vehicle is on a flat and level surface or the dipstick will provide an inaccurate reading. This is done best at a gas station where the surface is flat and even.

- Pull out the dipstick and wipe it off with a clean rag. The dipstick is connected to the oil tank in your engine and is used to determine how much oil is still in the oil tank. When the car is in motion the oil splashes around and covers the entire stick. To check your oil level you need to start with a clean stick. The dipstick is often located near the front of the engine. When you locate it, tug at it; it should pull out smoothly. Take care not to pull out the transmission fluid dipstick. If you’re not sure which dipstick is connected to the oil tank, check the user manual that came with your car, or ask a gas station attendant for help.

- Reinsert the dipstick. Carefully place the dipstick back into the pipe connected to the oil tank. Push it all the way down until it is completely reinserted. If it gets rattled or caught along the way, pull it back out, wipe it off, and try again.

- Remove the dipstick a second time to gauge the oil level. Look at the end of the dipstick to see where the oil’s film ends. The end of the stick will have the word “ADD” toward the end, and “FULL” toward the middle. If the oil film reaches up to or below the ADD line, it’s time to add more oil. If the oil film is close to the FULL line, you don’t have to add more oil quite yet.

- Determine whether the oil needs to be changed. In addition to checking the quantity of the oil, you should also check the quality. The oil should look clean and smooth. If the oil looks like it contains debris or looks cloudy, it needs to be changed.

How to Recycle Waste Oil?

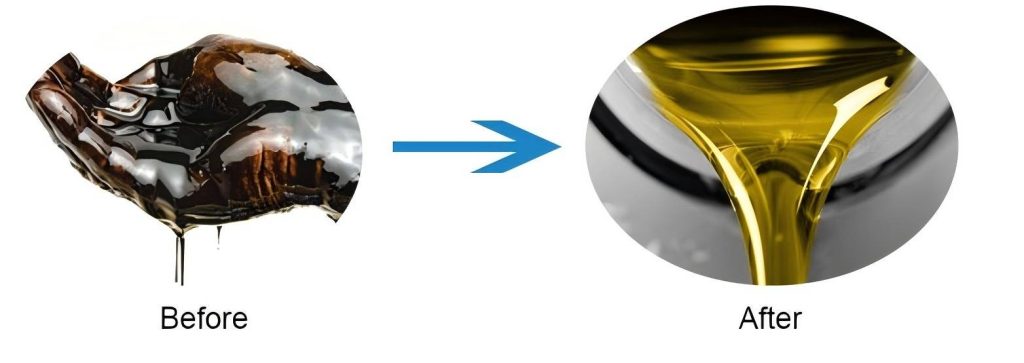

Once you think the quality of the oil is not suitable for continued use, the next step is to change the waste engine oil into the pure engine oil. But what should we do with the waste engine oil? Would you throw the waste engine oil freely or just burn the waste engine oil in an empty place. However, neither method is the best choice for drivers because the two methods do damage to the earth. The waste oil will pollute the soil and water in the earth and finally, it will harm people’s health. The wisest way is to recycle the waste oil with a waste oil recycling machine.

How to Recycle the Waste Oil Mixed with Various Impurities?

The first method is acid – clay process. This method is divided into several steps. The first step is to remove water from the waste oil. The waste oil recycling machine produced by Yangjiang can completely remove the water in the waste oil to obtain the dry waste oil for the next operation. The second step is to add sulfuric acid or hydrochloric acid to the pickling operation. The next step is to add the base and the preceding sulfuric or hydrochloric acid to get the neutral-treated oil. The fourth step is to add the activated clay to absorb the waste gas and impurities in the waste oil. Finally, the qualified oil can be obtained after filtration.

The second method is the distillation – solvent refining – clay process. The first step is to perform a flash operation to remove water from the oil to get dry oil. The next step is to add an alkaline solution to remove impurities in the waste oil to get a cleaner waste oil. Then distillation and ethanol or furfural extraction, and finally add clay refined waste oil, to get clean lubricating oil. This method is simpler than the previous one, and the result is a clean base oil. The two methods are different, but both produce a clean base oil, and both have many advantages and a few disadvantages. The above two methods of treating waste oil can be found in the products produced by Yangjiang, we can provide you with the best quality service.

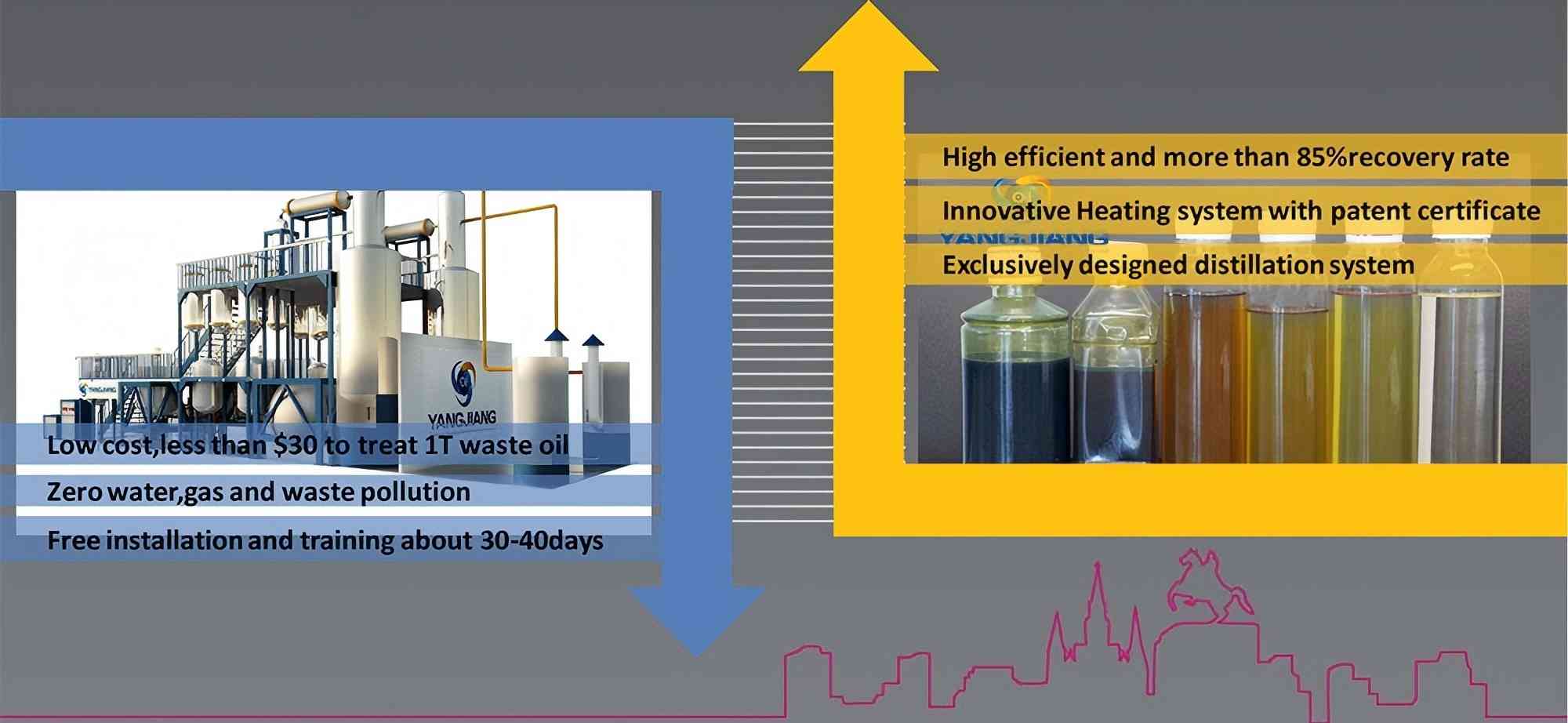

Main Technical Characteristics of the Waste Oil Recycling Machine:

- The key unit adopts vacuum catalytic cracking technology and chemical extraction technology.

- The machine is fully equipped with environmental protection equipment. Such as exhaust gas burners and flue gas collection chambers.

- Waste oil recycling plant adopts a simple chemical method to eliminate the color and peculiar smell of products.

- The machine has a recycling efficiency of over 85%.

- The design of the equipment is reasonable. The machine has the advantages of advanced manufacturing technology and strong operability. It is automatic and has complete safety facilities.

- The machine has multiple purposes.

The Advantages of the Waste Oil Recycling Plant

- High Efficiency and High Recovery: The waste oil treated by the waste oil recovery machine can get about 80-85% of the yellow base oil, which can be converted into various kinds of usable oil by adding compound additives. Gasoline and diesel can be made about 6 to 7 percent and can be used as fuel. Waste oil residue: 6.5%, can be used as fuel with some diesel. The water is about 1.5% and can be put into the pool as a cooling system for the machine. The advantage of doing so is not only to save costs but also to protect the environment.

- High Security: A useful machine is not only profitable but also safe. Our waste oil recovery machine can obtain yellow base oil under negative pressure. Most companies choose direct heating to cut costs. But it’s not safe.

- High Vacuum Environment: Waste oil can be better treated in a vacuum environment. Our waste oil recycling machine is equipped with a vacuum pump set. At least three vacuum pumps are provided to ensure the best operating environment and improve waste oil recovery.

- Low Price: Yangjiang adopts the highest-quality raw material to produce the waste oil recycling plant and waste oil distillation machine. Besides, the waste oil recycling plant price is well below our competitors. Once you decide to choose our product to dispose of the waste oil, we will provide you with the best after-sale service. Yangjiang will arrange the most professional technicians to ensure the smooth operation of the machine.