YJ-DSL Lube Oil Refinery Plant

Convert used-oil into diesel fuel through high temperature pyrolysis distillation.

The Importance of Recycling Used Oil into Diesel fuel?

- Firstly, the regeneration of waste engine oil into diesel can alleviate the problem of oil shortage. With the rapid development of the economy, the demand for oil continues to increase. Regenerated diesel from waste engine oil can effectively utilize waste resources, reduce dependence on imported oil, and thus ensure national energy security.

- Secondly, regenerating waste engine oil into diesel can help reduce environmental pollution. If waste engine oil is directly discharged or incinerated, it will cause serious pollution to the environment. By recycling, waste engine oil can be converted into diesel, reducing its negative impact on the environment and turning waste into treasure.

- In addition, the recovery of waste engine oil into diesel has significant economic benefits, and the market demand for regenerated diesel is high, which can create considerable economic benefits.

Specification of YJ-DSL Lube Oil Refinery Plant

| Function | Recycle waste oil into diesel |

| What kinds of oil can be recycle | Waste engine oil,motor oil black diesel,Industrial Lube oil,Transmission oil or the mixtural oil |

| Recovery Rate | 85%-90% |

| Heating method | electromagnetic heating system, burner, hot gas or tubular heating system |

| Warranty | 12 months |

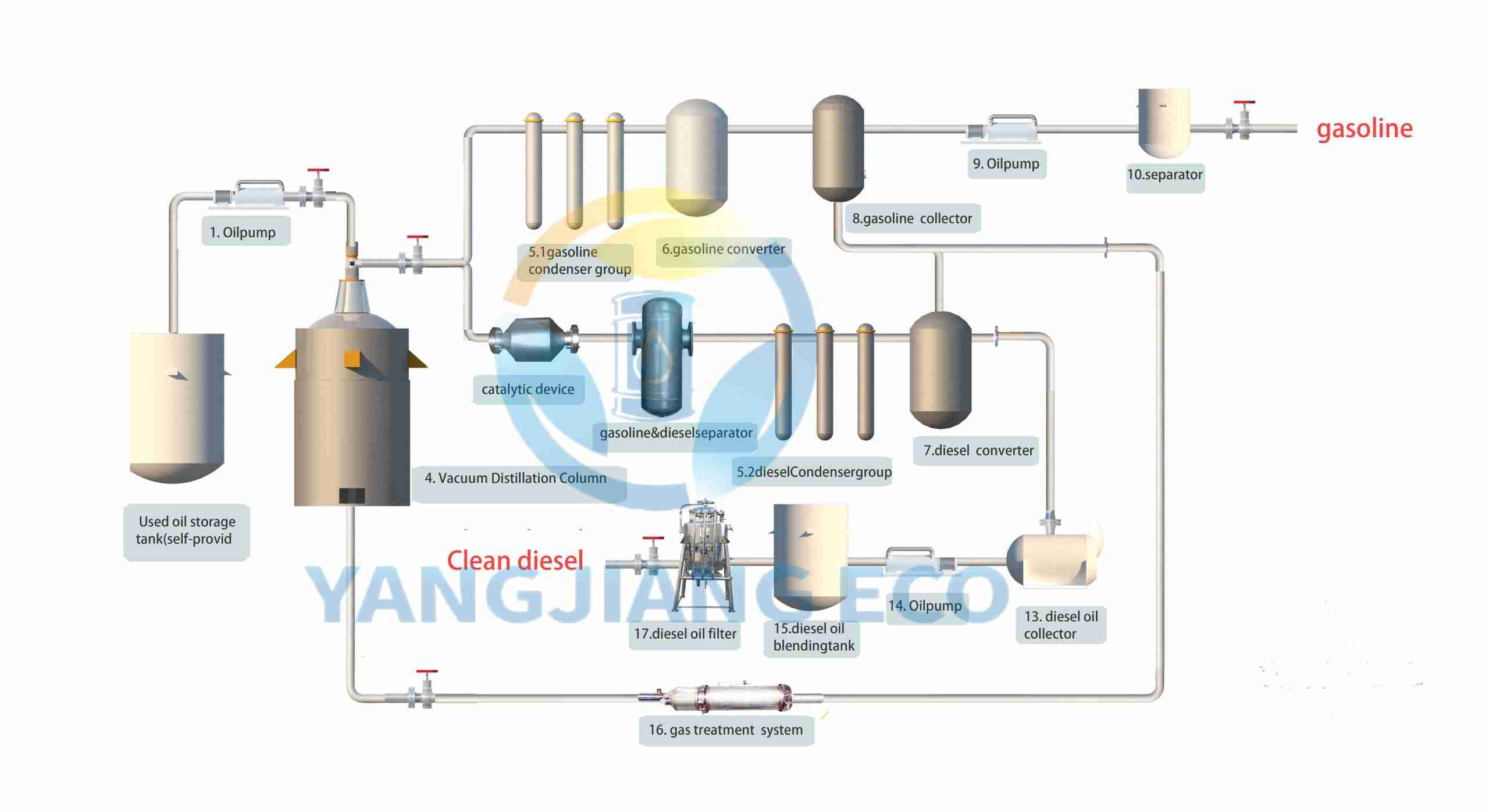

Working Process of YJ-DSL Lube Oil Refinery Plant

Oil can be used in many different products, and this is because of its composition of many different hydrocarbons of different sizes, which are individually useful in different ways due to their different properties.Cracking is a petroleum refining process in which heavy-molecular weight hydrocarbons are broken up into light hydrocarbon molecules by the application of heat and pressure, with or without the use of catalysts, to derive a variety of fuel products. Cracking is one of the principal ways in which used oil is converted into useful fuels such as motor gasoline, diesel oil and heating oil.Cracking breaks carbon-carbon bonds to turn heavier hydrocarbons into lighter ones.

Features of a YJ-DSL Lube Oil Refinery Plant

- High recovery rate: the highest recovery rate can reach 87-90%,including Gasoline 2-5%, diesel fuel 83-85%.

- Easy operation: The YJ-DSL series machine is easy to operate, low running cost, it need only 2-3 workers to operate.

- Rich raw material: YANGJIANG’s YJ-DSL series can recycle all kinds of used black diesel, used engine oil, used machine oil, used mineral oil and almost all industrial oil to diesel fuel. The cracked oil is able to be used as industrial or civil-use fuel, even power-driven fuel.

- Efficient catalyst: It is normally safe and available. It can help the waste oil further catalytic cracking to ensure a higher recovery rate and good quality of oil, the output oil can be used in ships, generators, as fuel for boiler, construction machines, Agriculture machines, etc. directly.

What Kinds of Catalyst We Use?

Yangjiang has been committed to researching and developing new technologies,continuously break through the oil recycling technologies,we have discovered this liquid catalyt through continuous experiments.The catalyst is safe to use, it won’t cause machine coke, Help to get better diesel color and diesel smell, lower sulfur content and pour point.

Many people use solid catalyst after distillation, we use it before, but the problem is the catalyst is easy to block or coke when hot oil vapor through the solid catalyst.It is normally safe and available. It can help the waste oil further catalytic cracking to ensure a higher recovery rate and good quality of oil, the output oil can be used in ships, generators, as fuel for boiler, construction machines, Agriculture machines, etc. directly.

Recycled Oil Report from YJ-DSL Lube Oil Refinery Plant

| Item | Test standard | result | Standard value |

| Density(15℃) | ASTM D1298 | 0.84kg/l | |

| kinematic viscosity(40℃) | ASTM D445 | 3.36cst | 1.6-5.8cst |

| Flash point(closed cup) | ASTM D93 | 60℃ | ≥55℃ |

| Pour point | ASTM D97 | -19 ℃ | ≤ 0℃ |

| Distillation temperature | |||

| 10% point | ASTM D86 | 204 ℃ | |

| 50%point | 289 ℃ | ≤300℃ | |

| 90% point | 344 ℃ | ≤355℃ | |

| 95% point | 359 ℃ | ≤365℃ | |

| Cetane index | ASTM D976 | 54.42 | ≥45 |

| Water content | ASTM D95 | Trace %vol | ≤Trace%vol |

| Sulfur content | ASTM D1226 | 0.151 %wt | ≤0.2%wt |

Production Process of YJ-DSL Lube Oil Refinery Plant

- YANGJIANG will provide PID, and LAYOUT before manufacturing the machine;

- Using high-quality raw materials from famous suppliers, Schneider or Siemens or equivalent brand electrical components can be chosen;

- PLC automatic controlled and explosion-proof motors;

- Leakage inspection and pressure test strictly after finishing making the machine;

- Engineers are available to go to the site to help install and commission the machine.

YANGJIANG has been committed to solving various waste oil purification problems, in addition to the above waste oil recycling plants, we also provide other used oil re-refining plants, such as Waste Oil to Base Oil Vacuum Distillation Plants, Diesel Desulfurization Machines , Base oil Solvent Extraction Machine, Base Oil Blending Plant, Transformer Oil Regeneration Machine.