YJ-DSL Used Oil to Diesel Oil Distillation Machine

Convert used-oil into diesel fuel through high temperature pyrolysis distillation.

Technology Description

Oil can be used in many different products, and this is because of its composition of many different hydrocarbons of different sizes, which are individually useful in different ways due to their different properties. The purpose of a refinery is to separate and purify these different components. Most refinery products can be grouped into three classes: Light distillates (liquefied petroleum gas, naphtha, and gasoline), middle distillates (kerosene and diesel), and heavy distillates (fuel oil, lubricating oil, waxes, and tar). While all of these products are familiar to consumers, some of them may have gained fame under their refined forms.

YANGJIANG uses high temperature cracking technology to recycle diesel fuel. Pyrolysis is a petroleum refining process in which heavy-molecular weight hydrocarbons are broken up into light hydrocarbon molecules by the application of heat and pressure, with or without the use of catalysts, to derive a variety of fuel products.

Application of YJ-DSL Used Oil to Diesel Oil Distillation Machine

YJ-DSL used oil to diesel oil distillation machine is widely applied in many industries to recycle and regenerate waste oils, including waste engine oil, motor oil, ship oil, industrial lube oil, hydraulic oil, gear oil etc, also can separate diesel oil form other fuel oil, By using catalytic pyrolysis process,high quality diesel fuel can be obtained from the waste oil with a high production rate. Yield diesel oil can be reused for generator, burner, ships or heavy machines, or construction machines directly.

Diesel oil distillation plant is available to work together with DSL model machine for reducing the sulfur to less than 50ppm, even to 20ppm, which can meet Euro-V related standards.

Technology Specifications of YJ-DSL Used Oil to Diesel Oil Distillation Plant

| Capacity | T / d | 0.5 | 1 | 2 | 3 | 5 | 10 | 20 | 25 | 30 |

| Base oil Recovery | % | ≤ 85-90% | ||||||||

| Temperature | ℃ | ≤ 420 -430 | ||||||||

| Working Noise | dB (A) | 45 | 60 | 60 | 65 | 65 | 65 | 70 | 70 | 70 |

| Motor Power | KW/h | 16.9 | 23.9 | 29.4 | 29.4 | 35 | 44 | 81 | 101 | 115 |

| Dimension MM | L | 4000 | 5000 | 8000 | 8000 | 8500 | 12000 | 18000 | 22000 | 23000 |

| W | 2500 | 3000 | 3500 | 3500 | 4500 | 5000 | 7000 | 8000 | 8000 | |

| H | 6000 | 7000 | 8000 | 8000 | 9000 | 10000 | 11000 | 11000 | 11000 | |

| Weight | Kg | 6500 | 9000 | 13000 | 14000 | 18000 | 22000 | 40000 | 50000 | 70000 |

| Cooling water | M3 | 25 | 30 | 30 | 40 | 60 | 100 | 150 | 150 | 200 |

| Opeating area | M2 | 100 | 300 | 300 | 400 | 400 | 600 | 900 | 1000 | 1500 |

| container | 1*20 | 1*20 | 1*40+ 1*20 | 1*40+ 1*20 | 1*40+ 1*20 | 2*40+ 1*20 | 4*40 | 5*40 | 6*40+1*20 | |

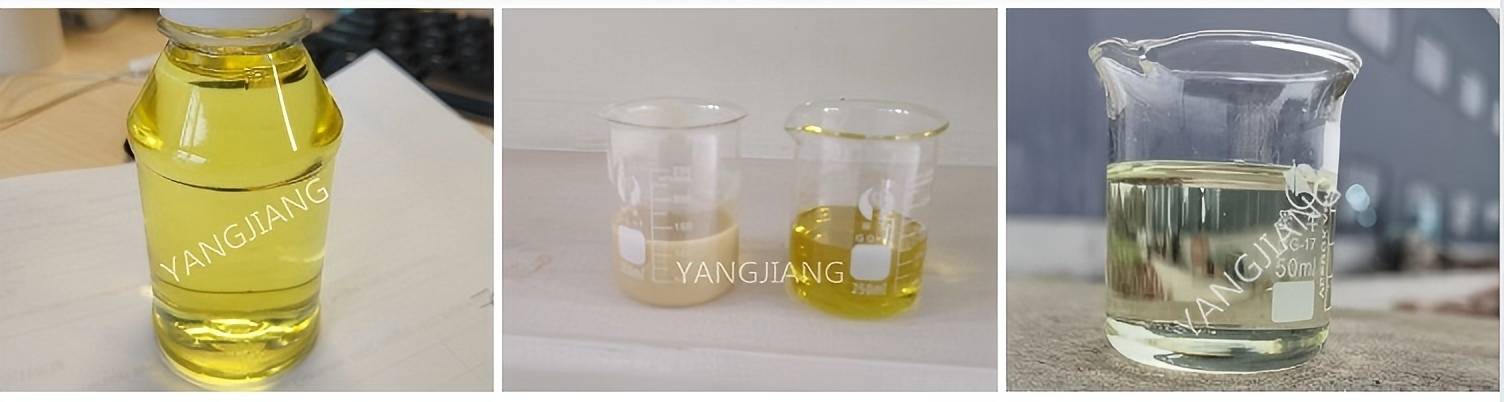

Oil Parameter by Used Oil to Diesel Oil Distillation Machine to Make Clean Diesel from Used Oil

| Item | Test standard | result | Standard value |

| Density(15℃) | ASTM D1298 | 0.84 kg/l | —- kg/l |

| kinematic viscosity(40℃) | ASTM D445 | 3.36 cst | 1.6-5.8 cst |

| Flash point(closed cup) | ASTM D93 | 60 ℃ | ≥55 ℃ |

| Pour point | ASTM D97 | -19 ℃ | ≤ 0 ℃ |

| Distillation temperature10% point50%point90% point95% point | ASTM D86 | 204 ℃289 ℃344 ℃359 ℃ | —– ℃≤300 ℃≤355 ℃≤365 ℃ |

| Cetane index | ASTM D976 | 54.42 | ≥45 |

| Water content | ASTM D95 | Trace %vol | ≤Trace %vol |

| Sulfur content | ASTM D1226 | 0.10 %wt | ≤0.2 %wt |

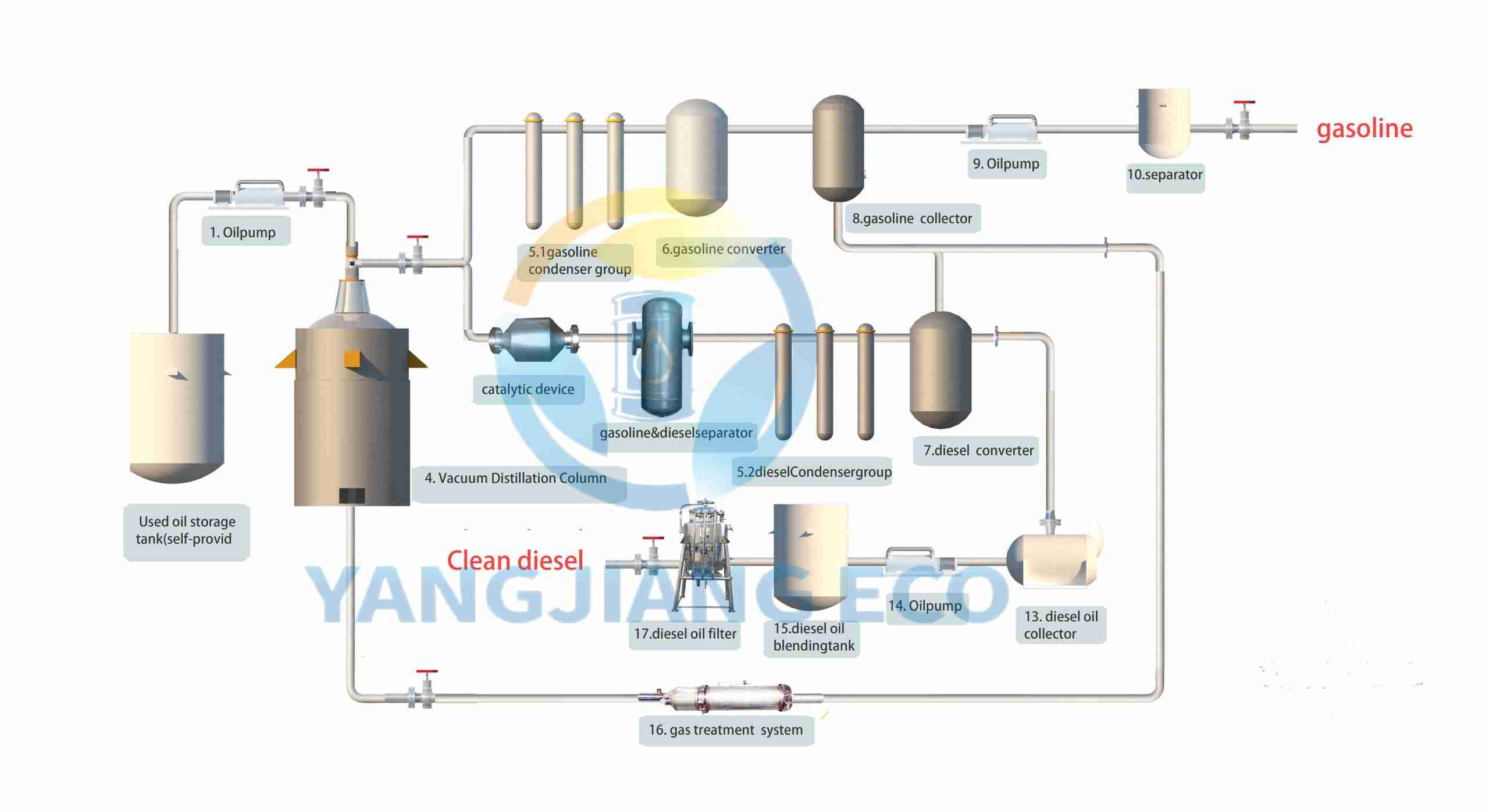

Flow Chart of YJ-DSL Used Oil to Diesel Oil Distillation Machine

Distillation Process Brief Description

- Reaction with Catalyst: we need to add alkaline chemical to neutralize waste oil acidity before distillation, otherwise increase the possibility of coking, affecting the running duration of the equipment and the quality of recycled oil.

- Distillation and Cracking: We heat the used oil by various heating methods till all cuts be distilled out, you can choose electromagnetic heating, fuel oil heating, natural gas heating, even used engine oil heating.

- Condensation and Collection of Water, Light Fuel and Diesel: As the temperature in the distillation unit rises, various cuts are liberated corresponding to various temperatures and rise as vapors, all after the vapors are condensed, we can collect different products in sequence, water, light fuel, and diesel fuel.

- Diesel Oil Further-Treatment: For the long-term storage and better stability, there are two oil further treatment options, one is clay or silica refining. Another further-treatment option is our YJ-SNC diesel oil desulphurization machine, which can remove 99%sulfur and nitrogen,reduce the sulfur content within 10ppm.and greatly improve diesel oil quality such as density, sulphur content, nitrogen content, acid value, carbon residue, flash point, pour point, cetane number etc

- Exhaust Gas Treatment System: With YANGJIANG exhaust gas treatment, the exhaust gas will be burned to oxidize and decompose the VOC compositions in the exhaust gas, so as to meet the requirements of “Overall Air Pollutants Emission Standards”.

Our Service

YANGJIANG will dispatch 1-2 engineers go to the site to provide further technical assistance, such as installation, testing and commissioning the machine, and also train or provide any other technical assistance.

Yangjiang has been committed to solving various waste oil purification problems,in addition to the YJ-DSL Used Oil to Diesel Oil Distillation Machine, we also provide other used oil re-refining plants, such as lube oil blending plant, and transformer oil regeneration machine.