YJ-SNC Diesel Desulfurization Machine

Desulfurization, denitrification and decolorization, reduce the sulfur content down to 10ppm

The Importance of Desulfurization

The sulfur content in diesel has a serious impact on the environment and health. The sulfur dioxide (SOx) produced after diesel combustion is one of the main pollutants in the atmosphere and an important indicator of whether the atmosphere is polluted. Diesel desulfurization is one of the important technical measures for preventing and controlling air pollution. Through desulfurization treatment, the SOx emissions generated by diesel combustion can be effectively reduced, thereby reducing air pollution, protecting the environment and human health.

With the increasing environmental requirements in recent years,the demand for high quality oil products is gradually increasing. Catalytic hydrogenation or hydrocracking is currently used in the market to remove sulfur, nitrogen and other undesirable components from oil. Although hydrogenation technology can treat the above impurities, its high equipment requirements, high temperature and pressure, high project investment, expensive and easily deactivated catalysts, and high processing costs make it difficult to meet the increasing requirements in terms of effectiveness, economy and safety. Therefore, it is crucial to develop new integrated fuel desulfurization, denitrification and decolorization technologies with small investment scale and low operating cost.

Technology Description of YJ-SNC Diesel Desulfurization Machine

This technology uses liquid additives to dissolve solids in it to form liquid Lewis acid based extractants. At the same time, the additives have unique planar structural characteristics, which can disperse the acidity of desulfurization and denitrification additives in the plane, thereby constructing a soft acid electronic structure. It can be seen that this technology can simultaneously achieve liquefaction of solid additives.

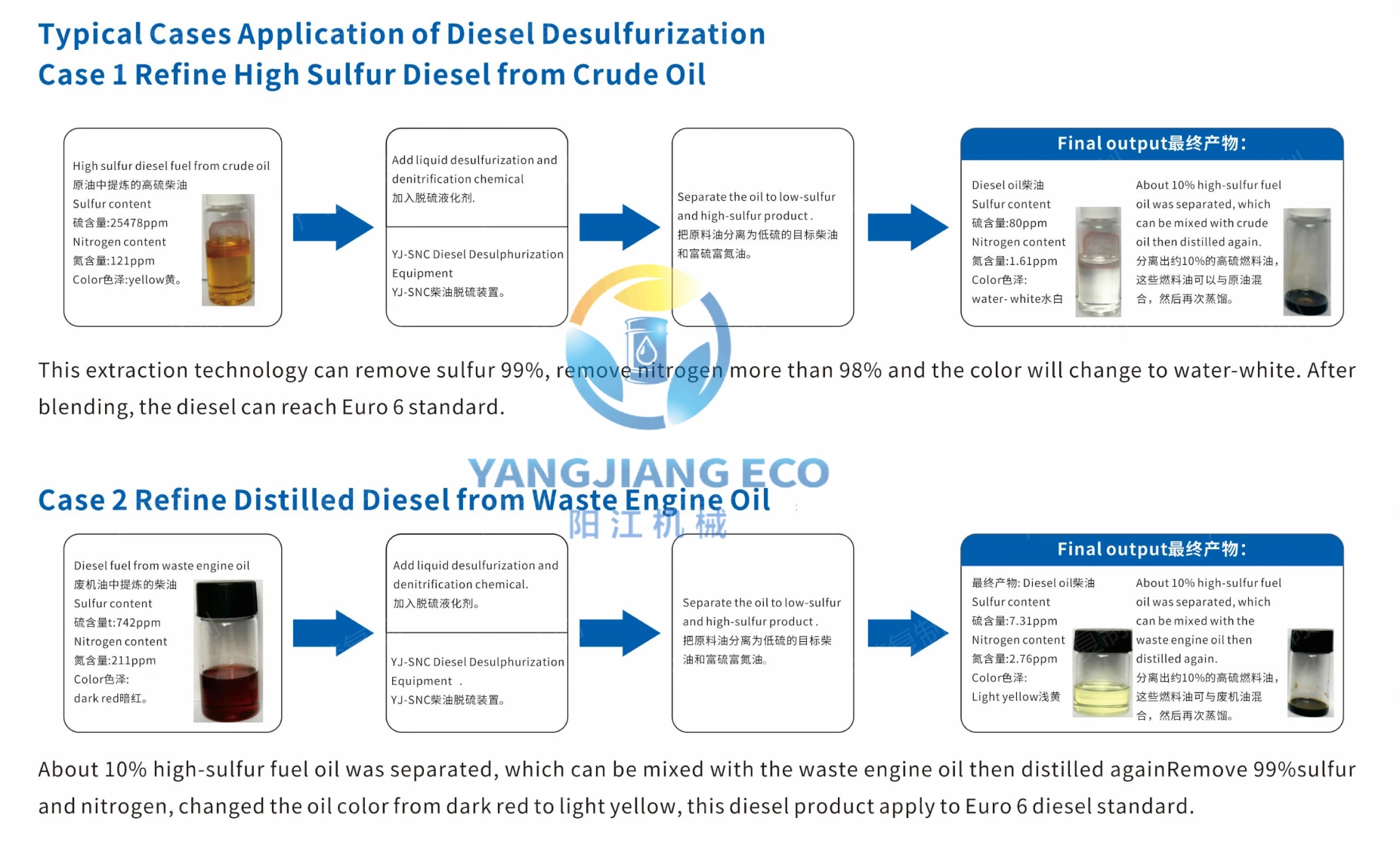

Application of YJ-SNC Diesel Desulfurization Machine

YJ-SNC Diesel Desulfurization Machine specializes in Deodorization, Desulphurization, Denitrification Refining Systems in One. Which is suitable for refine the following oil:

- Waste engine oil (distillation first)

- Diesel fuel from Crude oil

- Diesel oil from waste lube oil

- Black/red diesel

- Diesel fuel from Heavy fuel oil(HFO)

- Gas oil

Features and Advantage of YJ-SNC Diesel Desulfurization Machine

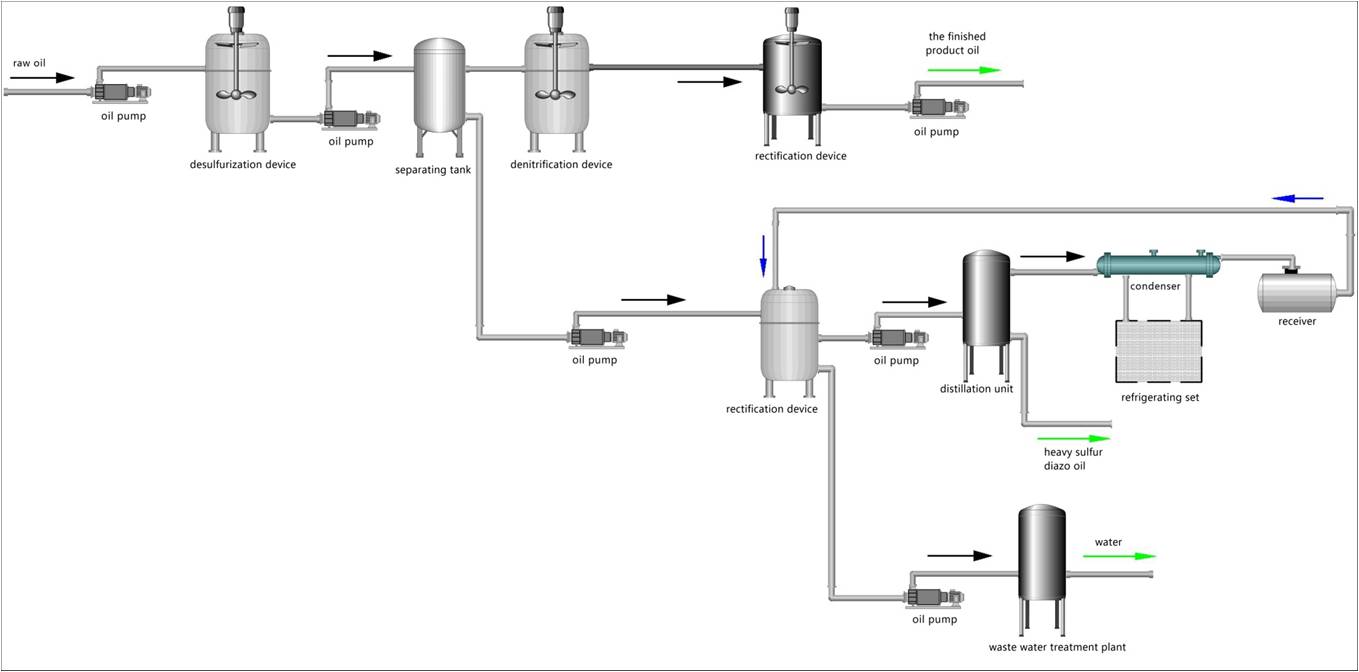

The focus of technology is separate the raw oil into low-sulfur diesel oil and sulfur-rich oil that can be distilled or extracted again.

- Around 0.5% Chemical consumption,the chemical additives can be recovered and reused again and again,and the additive is highly active even in normal pressure and temperature.

- Compared with hydrogenation technology,YANGJIANG’s desulfurization technology has significant advantages in terms of effectiveness, economy and safety.

- The liquid desulfurization and denitrification chemical can quickly dissolve the suspended solids in the oil to obtain a clear and transparent product oil, which can be recycled indefinitely;

- Zero pollution,No oily residue in the whole process.

- With a 100% recovery rate, the final oil output is essentially split into two parts: light-colored, low-sulfur and low-nitrogen product oil and dark-colored sulfur-rich and nitrogen-rich oil, with almost no oil loss.

- The sulfur can be reduced to less than 10ppm, which can meet the Euro V standard and can be directly used for cars.

FAQ

Yangjiang has been committed to solving various waste oil purification problems,in addition to the above waste oil recycling plants, we also provide other used oil re-refining plants, such as Used Oil to Base Oil Distillation Plant, Waste Oil to Diesel Oil Distillation Plant,,Base oil Solvent Extraction Machine,Base Oil Blending Plant,Transformer Oil Regeneration Machine