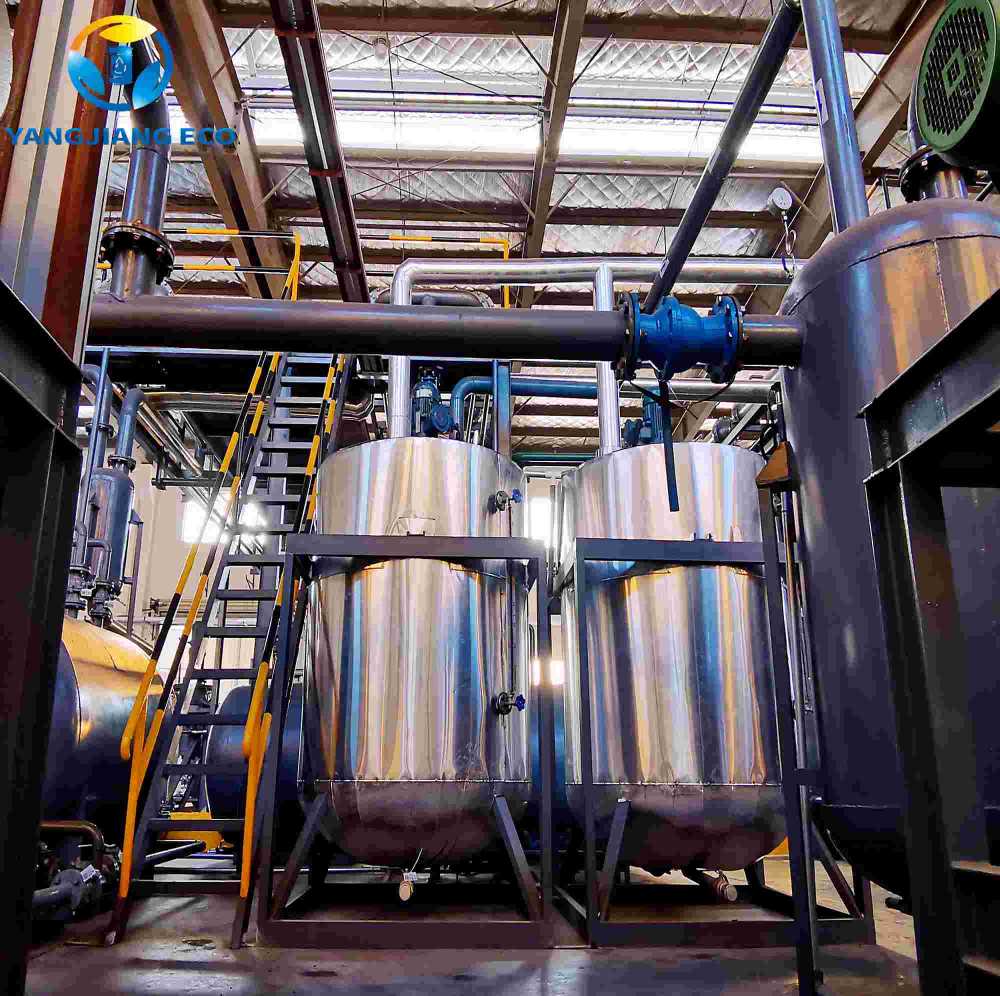

YJ-TY Lube Oil Recycling Plant for Used Oil

Our YJ-TY lube oil recycling plants can recycle all industrial used oil to a virgin base oil API Group I

- Base oil recovery rate: 75–85%

- Base oil color index: 1–1.5

- Acidity: ≤0.05 Mg KOH/g

- Technology: vacuum distillation

- Suitable oil: Used diesel engine oil, gasoline engine oil, motor oil, ship engine oil, truck oil, used hydraulic oil, and other used machinery lubrication oil, etc.

The Importance of Recycling and Reusing Used Lube Oils

Lubricants consist primarily of base oil, which makes up about 70%. The remaining 30% is oil additives, which are required for performance enhancement. These additives—dispersants, anti-wear agents, oxidation inhibitors, and viscosity index improvers—keep engines free from wear and corrosion and cool and clean. By combining base oil with these additives, various lubricants like hydraulic oil, gear oil, and engine oil are produced.

Although used oil is dirty, it is still a valuable resource. Even when lubricants are used with oil, they may be reused. Used oil can be re-refined to base lube oil, reprocessed into fuel oil, or used as feedstock to produce other commercially valuable materials. Proper handling and recycling of used oil not only avoids environmental contamination but also conserves an important non-renewable resource.

Application of Lube Oil Recycling Machine for Used Oil

YJ-TY lube oil recycling plant for used oil is particularly suitable to regenerate used engine oil, including diesel engine oil, gasoline engine oil, motor oil, ship engine oil, truck oil, and used hydraulic oil, and other used machinery lubrication oil into SN80, SN100, SN150, SN300, SN500 base oil.

It not only removes the impurities, water, and acid matter, organic and inorganic acids effectively, but also can remove carbon particulate matter and peroxides.

In gas/diesel engine oil, bitumen, and colloid, and other sludge can be removed similarly, and it can change the color to a golden color, removing bad odor. The output base oil can be reused for low engine or add different oil additives into it for producing hydraulic oil, gear oil, lube oil, or engine oil.

Technology Description of Lube Oil Recycling Plant

- YANGJIANG adopts vacuum distillation technology to remove contaminants from used oil, reducing pollution and enabling the oil to be recycled for reuse.

- Vacuum distillation works by lowering the pressure above the liquid mixture to less than its vapor pressure (usually below atmospheric pressure). This causes the most volatile liquids—those with the lowest boiling points—to evaporate and separate.

- The entire process is purely physical, involving no acids or chemicals. The machine simply distills out the components contained in the used oil without altering its quality or composition.

- Depending on the quality of the raw material, the base oil recovery rate reaches 75–85%, with a color index of 1–1.5.

Output Base Oil Parameters

| Item | Test standard | Data | |

| Light base oil | Heavy base oil | ||

| Viscosity(40℃) | mm2/s | 16~32 | 28~72 |

| Viscosity index | N/A | ≥99 | >110 |

| Appearance | N/A | Transparency | Transparency |

| Color index | ASTMD1500 number | ≤1 | ≤2 |

| Pour point | ℃ | -15℃ | -10℃ |

| Water content | %(w/w) | ≤0.05 | ≤0.05 |

| flash point(open) | ℃ | ≥180 | ≥210 |

| ash content | %(w/w) | 0.005 | 0.005 |

| carbon residue | %(w/w) | ≤0.13 | ≤0.13 |

| Corrosion(copper/100℃/3H) | N/A | Qualified | Qualified |

| Acidity | Mg KOH/g | ≤0.05 | ≤0.05 |

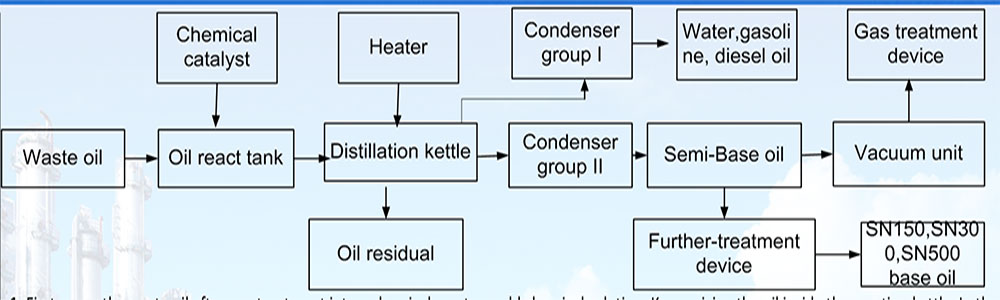

Flow Chart of Lube Oil Recycling Plant for Used Oil:

Process Brief Description of Lube Oil Recycling Plant for Used Oil

- Chemical Reaction (Neutralization): Before distillation, a catalyst (alkaline chemical) is added to neutralize the acidity in the waste oil.

- High-Vacuum Distillation: The neutralized oil is heated under high vacuum until all fractions are distilled. Heating methods include electromagnetic heating, fuel oil boiler/furnace heating, natural gas boiler/furnace heating, or even used engine oil heating.

- Condensation and Fraction Collection: As the temperature rises, different fractions vaporize at their corresponding temperatures. After condensation, the fractions are collected sequentially as water, light fuel, and base oil.

- Base Oil Additional Treatment: For improved long-term storage stability and general quality, there are two treatments:

- Clay or silica refining

- YJ-SR Solvent Refining Equipment: Makes base oil to API Group 1+ level, has water-white color oil as its output, and significantly improves such properties as viscosity index and content of saturated hydrocarbons.

- Exhaust Gas Treatment: The exhaust gas treatment system of YANGJIANG burns and breaks down the VOCs in the exhaust gas to enrich the “Overall Air Pollutants Emission Standards.”

- Base Oil Blending (Optional): For the production of lubricating oils, the YJ-BYL Base Oil Blending Plant can also blend base oil with additives to manufacture products such as hydraulic oil or engine oil.

YANGJIANG has been committed to solving various waste oil purification problems,in addition to the above waste oil recycling plants, we also provide other used oil re-refining plants, such as Waste Oil to Diesel Oil Distillation Plant, Diesel Desulfurization Machine, Base Oil Blending Plant, and Transformer Oil Regeneration Machine.