What Can YJ-TY Waste Engine Oil Refining Plant Do?

YANGJIANG YJ-TY waste engine oil refining machine is for recycling the waste engine oil into virgin base oil. In general, water and dissolved low boiling point organic removed by vacuum distillation. Lube oil is then recovered and fractionated by distillation. Light end by-products are commonly used for plant combustion fuels. Diesel and gasoline can be recovered as high-quality by-products after further advanced treatment. Residual streams from distillation can be used by the asphalt industry as an asphalt flux to produce roofing asphalt, paving asphalt, insulating materials, and other asphalt-based products.

What Technology Do We Use?

We use vacuum distillation to recycle used oil to virgin base oil API group I, light yellow with No1.5, Viscosity index 100, flash point 200℃

Comparison of Different Waste Oil Recycling Technologies

1. Thin Film Evaporation:

Thin film evaporators are typically of the scraper type. In the evaporator, the scraper forms a thin film of material, which offers an improved evaporation rate. During operation, the scraper is always in motion to offer uniform film thickness. The clearance of the inner wall of the scraper must be maintained at 0.5–1 mm, a requirement that requires high machining accuracy of the evaporator cylinder.

But the scraper is a wearout part and will gradually degrade. Once the clearance is greater than 1 mm, the processing effect is notably reduced. When used in waste lubricating oil processing, there are issues: waste engine oil contains organic acids, colloids, residual carbon, asphalt, etc., and other types of harmful impurities. These impurities will clog and block the scraper, causing the recycled oil to become red-yellow. Frequent cleaning and regular maintenance are required, and the replacement cost of the scraper is considerable. Thin film evaporators are therefore not well suited for processing high-viscosity lubricating oils but are perfectly suitable for processing low-viscosity fluids such as plant essential oils.

2. Vacuum Distillation:

The distillation point of a liquid is the temperature at which the saturated vapor pressure of the liquid equals the external pressure. This means the distillation point is a function of the external pressure. By lowering the system pressure through the use of a vacuum pump, the distillation point of the liquid can also be reduced. This principle is the theoretical basis for vacuum distillation.

Waste engine oil can be distilled entirely by high vacuum. Vacuum distillation has been employed worldwide for many years. It is more stable, less invested, and has simpler and more convenient operation and maintenance than molecular distillation. For all these reasons, vacuum distillation is more suitable for the treatment of waste engine oil.

Handling Capacity of YJ-TY Waste Engine Oil Refining Unit

The YJ-TY waste oil to base oil distillation plant can handle 1,000 liters to 100,000 liters within 24 hours. When selecting the best processing capacity, it is recommended to do some preliminary research on the waste oil market within your location.

- For beginners: For new entrants in the waste oil recycling industry, it is advisable to start with a mini refinery. Some facilities come in sizes of 500 liters, 2,000 liters, or 5,000 liters per day. The lowest processing capacity is 500 liters per day, and it is a good place to start.

- For experienced operators: If you already have experience in the business and a consistent source of waste oil, a medium or large refinery with higher capacity will allow you to reap more benefits.

YJ-TY Waste Engine Oil Refining Plant Technical Specifications

| Model | YJ-TY- 1 | YJ-TY-2 | YJ-TY-3 | YJ-TY-5 | YJ-TY-10 | YJ-TY-15 | YJ-TY-20 | YJ-TY-30 | YJ-TY-50 |

| Capacity(L/D) | 1000 | 2000 | 3000 | 5000 | 10000 | 15000 | 20000 | 30000 | 50000 |

| Working pressure PA | <50Pa | ||||||||

| Temperature ℃ | ≤330-350 | ||||||||

| base oil recovery rate | 80-85% | ||||||||

| motor power consumption KW/H | 32 | 41.5 | 41.5 | 61 | 76.2 | 97.1 | 139.5 | 169.5 | 219 |

| Fuel consumption per recycle 1000L waste oil | 35 | 30 | 30 | 25 | 25 | 20 | 20 | 20 | 20 |

| Dimension MM | 5000 | 8000 | 8000 | 8000 | 12000 | 14000 | 20000 | 25000 | 40000 |

| 3000 | 3500 | 3500 | 4000 | 6000 | 8000 | 12000 | 20000 | 30000 | |

| 600 | 7000 | 8000 | 8000 | 9000 | 9500 | 11000 | 1100 | 11000 | |

| Weight (KGS) | 12000 | 16000 | 18000 | 24000 | 33000 | 40000 | 49000 | 65000 | 90000 |

| cooling water | 60 | 60 | 60 | 70 | 80 | 100 | 150 | 200 | 300 |

| operation worker | 1-2 | 2-3 | 2-3 | 2-3 | 3-4 | 3-4 | 4-5 | 4-5 | 5-6 |

| delivery time | 30 | 50 | 50 | 60 | 80 | 90 | 100 | 120 | 150 |

| containers | 20′ | 40’+20′ | 40’+20′ | 2*40′ | 2*40’+20′ | 3*40′ | 4*40′ | 6*40′ | 8*40′ |

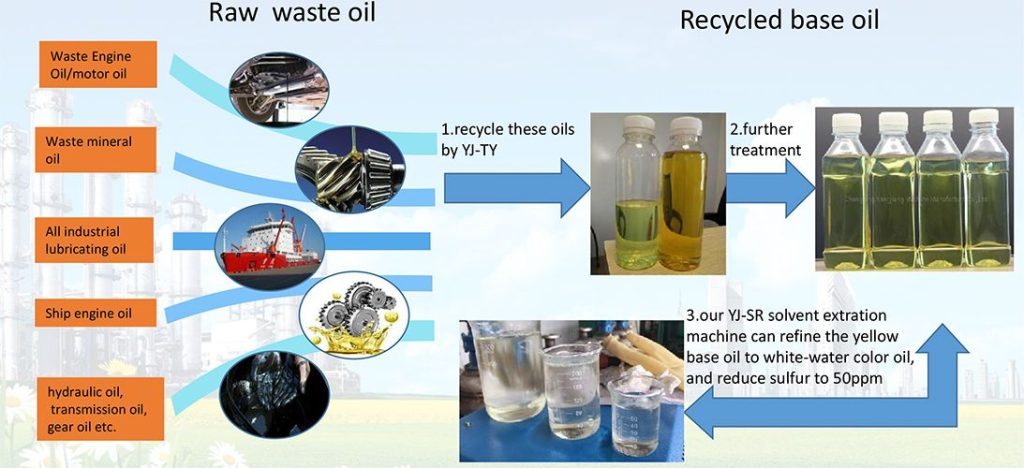

What Kinds of Waste Oil Can Be Recycled?

The YJ-TY waste engine oil refining plant can recycle all kinds of lube oil, engine oil, motor oil, waste mineral oil,ship oil, transformer oil, hydraulic oil, gear oil, all used industrial lubricating oil.

What Kind of Oil Can We Get from YJ-TY Waste Engine Oil Refining Plant?

The YJ-TY series can recycle various kinds of waste oils into near-virgin API Group I base oils with a light-yellow color and a flash point of 180–220 ℃.

With the raw material as diesel waste engine oil from the Chinese market, the YJ-TY system recovers the base oils such as SN80, SN100, SN150, SN200, SN300, and SN500 at a recovery rate of 75–85%. The recovered base oils may be blended to give a range of lubricants or greases.

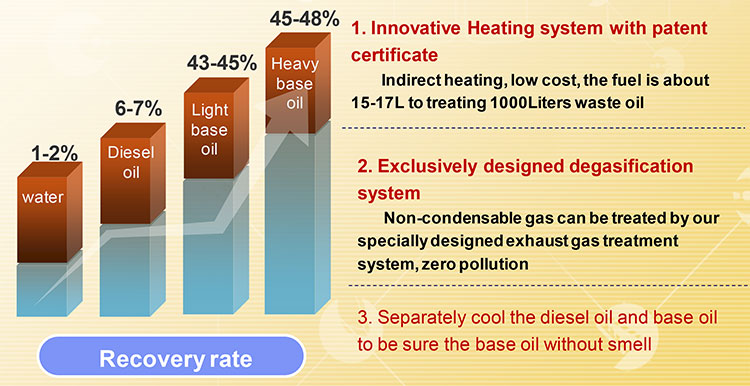

In addition to the base oil, the process also recovers:

- 5–7% light fuel, recoverable as fuel oil.

- 2–3% water, recyclable as cooling water.

- 7–10% as oil residue, which itself is utilized as fuel or asphalt.

| Items | Temperature | Recover rate |

| water | 80degree | 2-3% |

| Gasoline and diesel | 180degree | 5-7% |

| Light base oil | 280degree | 42%-43% |

| Heavy base oil | 330degree | 40%-43% |

| Residual | 7%-10% |

What Heating Methods Do We Use in YJ-TY YJ-TY Waste Engine Oil Refining Plant?

Customers can choose electromagnetic, diesel, natural gas, or even used oil as the heating material. Electricity and fuel oil are more suitable for small-scale refineries, while the fuel furnace is usually used in large-scale waste oil refineries.